Truck Tyre Maintenance Tips for Harsh Mining and Off-Road Conditions

Date: 03 January 2026

Mining truck tyres, or off-road tyres, go through harsh conditions during their operations. The jagged rocks shred sidewalls, mud clogs deep lugs, and excessive heat leads to catastrophic failure. Worst case? Overloaded axles lead to faster tyre wear and fatalities as a result.

Mining tyres are designed to work effectively under these conditions. But even the strongest tyre fails without disciplined maintenance. Proper maintenance can extend tyre life 25-50%, slash downtime, and boost fleet ROI.

This comprehensive guide will help you with some truck tyre maintenance tips for mining tyres and how to maintain them in harsh off-road conditions.

Why Mining and Off-Road Harsh on Tyres

Picture this: 40-ton dumpers crawling over jagged quartz, temps hitting 50°C, zero grip in slurry pits. That's not the job for regular tyres.

Mining demands OTR (off-the-road) tires that come with deep lugs, cut-resistant compounds, and heat shields. Off-road hauls add vibration, uneven loads, and sidewall snags. That's why it's important to follow regular off-road tyre maintenance.

Stay Ahead of Equipment Failure: Discover the 5 critical checks that extend mining tyre life.

8 Truck Tyre Maintenance Tips for Longer Tyre Life

Here are some maintenance tips for mining vehicle tyres for a longer lifespan and better tyre life:

1. Daily Pre- and Post-Trip Tyre Inspections

Time Required: 5-10 minutes per vehicle.

Start every shift with a visual walkaround—Birla stresses this catches 80% of failures early.

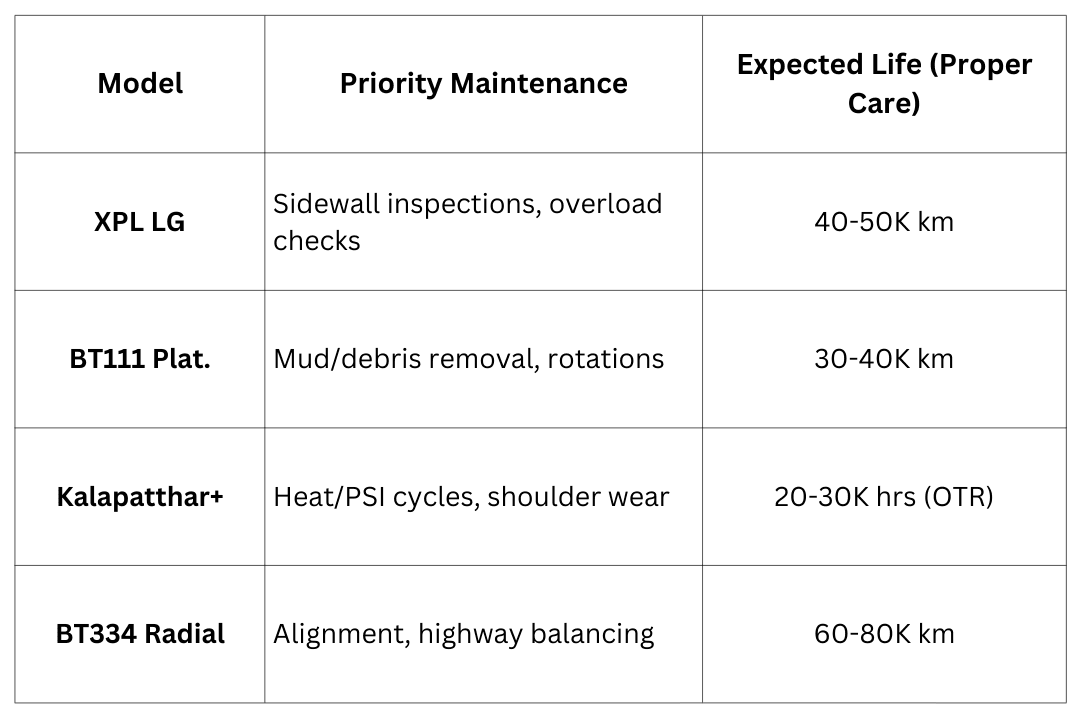

- Sidewalls: Inspect for cuts (>6mm deep = replace), bulges, and exposed cords. XPL LG's extra plies resist impacts, but plug minor punctures immediately with radial plugs.

- Tread: Check depth (min 2mm; use gauge), irregular wear (feathering = misalignment), embedded debris. BT111's cross-lugs trap shale; remove with pick/air.

- Valves/Caps: Tight, undamaged. Rust signals leaks.

- Post-Haul: Heat check (hand-test casing <60°C), fresh damage scan.

2. Manage Tyre Pressure

Incorrect PSI causes a significant number of premature failures. Always check the tyre pressure cold, especially when the vehicle is parked and shaded for more than three hours before driving.

Hot tyres may give a false high reading. Cold tyre pressure, on the other hand, provides more accurate PSI for longevity & safety.

- Load-Specific: Refer to sidewall tables. For empty mining trucks, go for +15-20% above rated. For loaded trucks, follow an exact match.

- Example: 10.00-20 XPL LG (12-tonne axle): 90-100 PSI loaded.

- Nitrogen Fill: Fill the truck tyres with nitrogen for 20% steadier performance compared to air.

- Hot Checks: If pressure jumps 20+ PSI when hot, slow down and lighten the load. Recheck after cooling off.

3. Rotate Tyres on Time

Mining tyres wear twice as fast during their mining operations. It leads to uneven wear, leaving thinner areas in some parts of the tyre. On the flip side, the other parts of the tyre remain intact, weakening the tyre in the process.

However, moving them around every 5000 kms helps get rid of that problem. The rotation can be from the front to back, or side to side.

When Heat Is the Challenge: Learn how nitrogen improves safety and performance in mining environments.

4. Don't Overload

Don't put too much weight on your off road tyres. Yes, mining operations are demanding. But adding more weight than suggested can bend the tyre sidewall and cause it to pop. Here are some truck tyre maintenance tips to manage overloading:

- Use the weighbridges coming and going.

- Spread the load evenly, more on the back wheels off-road.

- Check shocks every few months.

Birla's strong tyres handle a bit extra short-term, but steady overload cuts life in half. So, keep that in mind when loading your mining vehicle.

Discover the Engineering Edge: Explore the science powering Birla Tyre’s extreme-performance OTR tyres in 2026.

5. Watch the Heat

- Speed Discipline: Hot mines wear the tyres pretty fast. So, go slow when driving in harsh conditions. Maintain a speed of under 40 km/h.

- Cooldown Protocol: Let the truck idle 30 minutes after hard work before parking.

- Shade Storage: Store in shade with tarps

- Monitoring: If shoulders feel super hot, give them a break.

Birla Kalapatthar+'s compound resists better in mines. But you can add life to the tyre by maintaining its heat.

6. Cleaning, Repair, and Retreading Protocol

- Weekly Wash: Focus on the lug channels and do a high-pressure wash once a week.

- Punctures: check for punctures and tyre repair on time.

- Retreading: Remember to retread if necessary.

- Storage: Store standing up, cool and dry.

Repairing off-road tyres on time extends 30% life; neglecting them packs an imbalance.

7. Alignment, Suspension, and Brake Integration

Crooked wheels eat edges fast. Check every 10,000 km (monthly in mines). Also, fix shocks and brakes, too. This little attention saves 5-10% fuel.

8. Smart Gadgets Help

Tyre pressure alarms tell you instantly if it's low. That's why tools like TPMS, with real-time tyre pressure data, are available. Additionally, track tyre rotations with tags. See wear bars? Time to replace.

Reliability in Your Hands.

Birla Off-road tyres for mining operations extend a helping hand to truck and dumper operators and users. Although built with tough materials, users can extend the lifespan of tyres with regular maintenance and proper tyre care. Daily PSI, inspections, and rotations form 80% of success.

However, skipping them has higher budgetary implications. So, take the reliability of the off-road tyres in your hand by regularly following the truck tyre maintenance tips mentioned in this article.

So, what’s your toughest terrain challenge?