Beyond the Wheel: 5 Critical Checks for Your Mining Bias Tyres

Date: 30 December 2025

Expenses on tyres account for a significant share of mining operations' costs. In fact, it's among the most safety-critical components of mining vehicles.

The majority of premature tyre failures on mining grounds can be traced back to preventable issues. Premature tyre failures could be linked to improper inflation, overheating on the tyre, mismatched duals, underfoot hazards, and over-payload conditions.

Mining operations and haulage trucks operate under extreme conditions, including high ambient temperatures, abrasive terrain, and occasional extra loads. Where a small oversight is enough to multiply risks for mining vehicles, maintenance, and regular checks are non-negotiable.

A structured inspection routine aligned with the manufacturer's recommendations ensures consistent performance and safety of the operators. As manufacturers of durable Kalapatthar and Kalapatthar+ mining tyres, we at Birla Tyres can suggest a thing or two about the right mining bias tyre maintenance routine.

Check #1 — Inflation & Deflection

Tyre inflation and deflection are critical to maintaining the tyre structure and performance in the long run.

Why it matters

Both over-inflation and lower inflation affect the off the road bias tyres’ construction. Incorrect inflation affects the natural deflection of these tyres, which support the cross-ply pattern of the mining bias tyres. It increases sidewall flexing and internal heat generation. In short, overinflation or underinflation can affect the tyre's deflection in two ways.

First, over-inflation stiffens the tread area of the tyre, reducing its traction and shock absorption on the mining grounds.

Second, chronic under-inflation softens the bias ply structure, causing cracks and separations, while over-inflation stiffens the tread area of the tyre.

The best way to inflate the tyre is by staying within the pressure-load range provided by the tyre manufacturer, and according to how the tyre is tuned for its service type. Overloaded and underinflated tyres are vulnerable in rigid dump applications where braking loads and torque concentrate at the centerline.

How to check

- Measure cold pressure before each shift starts and the vehicle starts moving.

- Log any deviation of ±5% or more. Next, inflate the tyre as per the correct specification.

- Look for valve stems and caps for damage and leaks.

- Refer to the payload plan of any shift. Adjust the pressure when hauling denser material or operating on hotter and longer routes.

Birla assist

Follow the vehicle manufacturer's recommendation for mining tyre inspection and regular checks. If you're using Kalapatthar, Kalapatthar+, or Ultra Trac DX bias OTR ranges by Birla Tyres, check out the pressure recommendation under "Technical Specifications" on the Birla Product Page.

Our off-road and mining tyres are specifically designed for the abrasive mining road conditions. Finally, don't forget to consult Birla's technical data tables or contact their field engineers for exact inflation levels by size and ply rating.

Check #2 — Tyre Temperature Management

Managing tyre temperature as part of your tyre inspection routine helps predict unprecedented liner damage and blowouts.

Why it matters

Most tyre manufacturers recommend a cooldown roughly every two hours during long hauls. This cooldown period allows temperature equalisation. It's a critical practice to consider for the bias ply construction of the mining tyres.

Overheated mining tyres can experience ply separation, liner damage, and sometimes blowouts on the field. Ensure to include tyre temperature management in your mining tyre inspection routine.

How to check

- Use TPMS or wheel‑end temperature sensors wherever installed.

- Flag tyres that are running hotter compared to the axle average.

- Don't park hot tyres on freshly blasted or sun-baked surfaces. Doing the opposite traps and raises the radiant heat in the tyre, increasing the chances of damage and blowout.

- Review your mine's cycle data versus the tyre's Ton‑Kilometre‑Per‑Hour (TKPH) rating.

- If ambient temperature, payload, or travel length push conditions towards the TKPH limit, enforce cooldown SOPs such as mid‑cycle rest or reduced haul speed.

- Long‑term, compare your temperature logs across shifts.

- Establish site thresholds with your tyre supplier. When the combination of ambient, load, and cycle length exceeds the bias casing's safe TKPH, enforced cooldowns will significantly reduce heat separation events.

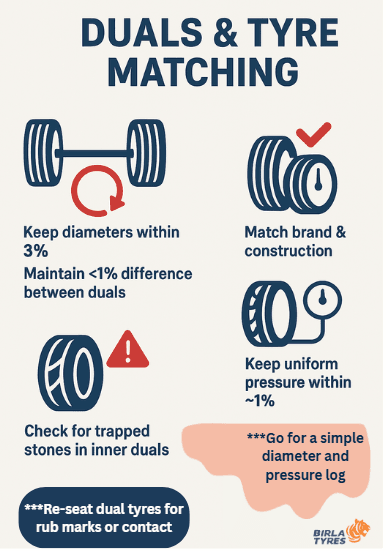

Check #3 — Duals & Tyre Matching

Consider the wheel diameter, wear, and pressure tolerance of your tyre as part of your tyre inspection routine.

Why it matters

Often, rigid dumpers run on a dual tyre configuration. While this may seem cost-effective to some users at first, it has adverse effects in the long run. Vehicle manufacturers recommend using the same configuration on a pair of tyres. Using dual configurations, with flex differences, or minor diameter or pressure mismatch can lead to multiple difficulties. For example:

- One of the tyres ends up carrying more weight.

- One tyre can build up more heat while the other wears out rapidly.

- The overstressed tyre ends up holding back the durable one, leading to premature casing failure.

That's why consistent dual pairing protects both tyre investment and vehicle balance.

How to check

- Keep left-right tyre diameters within 3% differences and maintain less than 1% difference between duals on the axle.

- Match your tyres according to brand and ply construction to avoid a mismatch.

- Keep the tyre pressure uniform within about 1% across each mounted pair.

- Look for trapped stones or debris in the inner duals as part of your tyre inspection routine. These stones and debris can cut the sidewall or cause rubbing.

- Remove and re-seat the duals when you see rub marks or contact between them during tyre inspection.

- A simple diameter and pressure log can save multiple casings from early removal.

Check #4 — Underfoot & Haul‑Road Inspection

Mining haul road inspection is just as important as inspecting mining bias tyres. Regular checks and removal of hidden hazards on mining grounds, along with fixing grades & curves, adds substantial time to mining fleets' tyre lifespan.

Why it matters

Bias OTR tyres are durable and can operate in harsh haul-road conditions. But no tyre is invincible against poor road conditions. Sharp shot-rock fragments, uneven grades, and standing water are common in the harsh mining terrains. These road hazards contribute to massive tyre fatigue and damage. Site engineering—particularly haul‑road design—directly influences tyre cost per hour.

How to check

- Conduct regular tyre inspection patrols along haul segments. Check for sharp rock spillage and debris. Remove any hazards immediately upon finding.

- Puddles and standing water often hide sharp stones that slice lugs or the tyre sidewall. Eliminating these conditions on the mining grounds reduces the chances of tyre damage.

- Maintain road grades between 5–8%, the ideal compromise (according to ResearchGate) between haul efficiency and traction control.

- Remember: each 1% change in grade alters load by roughly 2%, raising rolling heat and fuel use.

- Where haul‑road curves exist, super‑elevate to counter lateral stress, and cap vehicle speeds to maintain stability.

- Carry out routine audits combined with visual surveys with a drone or 3D mapping for slope and curvature analysis.

- Addressing structural haul‑road issues reduces both tyre wear and suspension maintenance costs.

Check #5 — Damage Inspection & Rotation

Inspect for damages such as cuts, sidewall bulges, and the need for tyre rotation on your mining vehicle.

Why it matters

Negligence after a mining tyre inspection can result in heavy expenses for damage recovery. Drivers and operators often neglect cuts and imbalanced wear even when it's right in front of their eyes. What this does is escalate into a severe structural separation, or blowout.

Additionally, uneven wear between axles or wheel positions is another driver of the tyre's hidden cost. For dump trucks, the heavier rear tyres wear out faster. The solution to this is regular rotation. It helps reduce stress, balance tread wear, and extend the total life of the tyre.

Bias tyres, thanks to their thicker carcasses and robust sidewalls, often allow field repairs, but only when properly assessed for structural integrity.

How to check

- Maintain a 360° inspection at both the start and the end of the shift.

- Record the tread depth readings at consistent clock positions. Additionally, compare patterns by wheel locations.

- Align regular tyre inspection with lug nut inspection, torque level, and wheel integrity. Oxidation and corrosion can loosen mating surfaces.

- Inspect mining tyre wear patterns and prepare rotation schedule accordingly. Maintain a rotation schedule according to wear patterns. It's best to move the most worn tyres to lower stress positions.

- Isolate a tyre with cuts, bulges, or exposed cords immediately and seek a technician's evaluation.

- Follow OEM standards to judge repairability; never compromise casing safety.

- Many mines adopt predictive maintenance dashboards that integrate tread depth, heat, and pressure data. Doing so transforms manual checks into preventive, data‑driven tyre management.

From Birla Tyres to Mining Operators

As one of the most established OTR manufacturers of India, we integrate decade-long research and field data into the engineering of every product. According to our findings, bias-ply construction has constantly performed in the harsh, heavy-duty, and quarrying terrains of the Indian mines. The best mining tyres are always terrain and application-specific.

Additionally, maintaining routine checks and following the five mining tyre inspection parameters should help you increase the tyre's lifespan without compromising on fleet performance and profitability.

If you're using any of Birla Tyres' products for off-road and mining vehicle use, refer to the technical documents and tyre-specific guidance for detailed recommendations. Consult Birla Tyres for further information on tyre inspection and the right fit for your mining vehicle.

FAQs

What Are Mining Tyres?

Mining tyres are the ones intended for heavy-duty use cases at mining grounds. Tyres such as Birla Kalapatthar are built to withstand the harsh terrains of mines. These tyres feature a robust tread pattern design to operate under heavy-duty haulage requirements at mines.

How to Inspect the Mining Tyre Condition?

Look for damages like cuts, bulges, and exposed cords on the tyre. It also helps to check proper tread depth and inflation on the tyre to spot early signs of damage.

What is the 3% Rule for Tyres?

As a general rule, you must replace your tyres with ones that are within 3% of the diameter measurement of the original tyres on the vehicle.