Engineering Giants: The Science Behind Birla Tyre's Extreme-Performance OTR Tyres in 2025

Date: 23 December 2025

From open-cast mines to industrial ports and construction corridors, Off-The-Road (OTR) equipment operates in places that punish components every minute of the day.

In such environments, tyres aren’t just consumables; they are mission-critical parts that determine safety, productivity, and the cost per tonne moved. In 2025, tyre technology has grown beyond demand, combining material science, digital simulation, and application-specific tyre tread engineering.

As a leading brand for off the road tyres in India, we have long held the heritage of manufacturing off-highway and OTR segment tyres with a robust R&D roadmap. While our focus is on sustainability, performance, and cost efficiency, we have faced critical off-road challenges along the way to deliver the final product to users successfully.

Understanding OTR Tyre Challenges

These tyres are for loaders, graders, cranes, and other off-road rollers. The core functions of these tyres are to provide traction, stability, and durability while carrying a massive load.

Maximise Bias-Ply Tyre Life: Discover expert tips to improve durability in heavy-duty and off-road operations.

OTR tyres face the following challenges while fulfilling their core functions:

Load Impact: The sheer mass the tyres support introduces extreme stress on casing and bead areas.

Terrain Abrasiveness: OTR tyres are capable of managing rock cuts, embedded debris, and sharp edges. Sharp stone edges and rock cuts reduce the durability and the life cycle of the tyre.

Heat management: Although capable of managing heat, OTR tyres take immense impact during long-duty operations. It can lead to premature wear and thermal degradation, reducing the tyre’s lifespan.

Operational Safety & Uptime: Failures can halt production lines or mine benches, so tyre reliability and predictable wear are vital.

Stay Ahead in Mining and High-Heat Applications: Discover how nitrogen improves tyre safety and performance in extreme industrial conditions.

Birla Tyres’ OTR Range: Built for Extreme Conditions

Birla’s OTR portfolio is organized by service (TRA codes) and application. The tyre technology ensures that each pattern fits into a specific machine and duty cycle. The key products of the tyre Birla off-road range include the following:

Kalapatthar & Kalapatthar+ (TRA ML – Mining, Rock; Bias construction):

Designed for the toughest mining environments, these tyres have a thick casing and deep cut-resistant tread compounds. What it does is provide bench stability and reduce downtime. The tyre size can vary between 9.00-20 and 12.00-24, depending on the variant.

Ultra Trac (TRA E3/E4 – Earthmover)

The Ultra Trac is built for earthmovers and dump trucks that require a combination of traction and heat-resistant compound in their tyres. They are equipped with the capability to equally handle long hauls and heavy loads. The tyre size varies between 12.00-24 and 24.00-35.

Choose the Right Tyre with Confidence: Learn how tyre size and markings impact safety, comfort, and efficiency.

Grader Max (TRA G2 – Grader)

Grading tasks depend more on directional control and balanced traction. The rib and lug geometry of the Grader Max is good for blade work. (Common sizes: 13.00-24, 14.00-24.)

Ultra Grip (TRA E3/L3 – Loader)

Wheel loaders in construction sites and mining grounds demand aggressive traction and a strong sidewall for protection against rock impacts. That’s where the Ultra Grip by Birla Tyres performs efficiently. The treads, tread blocks, and the void ratios are optimized for debris ejection and grip. (Size range: 14.00-25, 17.5-25, 20.5-25, 23.5-25, 26.5-25, 29.5-25.)

Loader Max (TRA R4 – Industrial)

Another efficient tyre suited for industrial loaders, Loader Max, performs well against mixed surfaces where even wear and traction are of optimal requirement. (E.g., 16.9-28.)

Ultra Port (TRA IND-4 – Industrial Port)

Engineered for port machinery—reach stackers and forklifts—where stability, slow speeds, and heavy static loads are common. (E.g., 18.00-25.).

F Trac (TRA IND – Industrial)

A general industry duty with lug/traction patterns to provide grip and cut-resistance against sharp particles at operating sites. Featuring robust treads, F Tracs have cleaning designs.

Ultra Slick (TRA L-5S – Smooth, Underground Mining Tyres)

Smooth tread for underground operations maximizes contact area and cut resistance, minimizing chunking in tight tunnels and abrasive surfaces. (E.g., 26.5-25.)

The Science Behind Birla’s Tyre Technology

From the use of advanced materials to the development of application-specific treads, we ensure that science and experimentation empower every product decision.

Advanced Material Engineering

Birla’s recent R&D narrative spotlights polymer grafting. The enhanced tyre material properties are engineered at the molecular level. This engineering ensures that the tyres receive better tear strength, cut resistance, and thermal stability.

Built to Last, Maintained to Perform: See how Birla Tyres supports long-lasting performance with the right care practices.

Bias Construction Choice

Birla OTRs with multiple crisscrossed plies build a robust construction from bead to bead, forming a rigid sidewall and stout footprint. Heavy-duty vehicles with slow driving capabilities benefit from the bias ply constructions of Birla OTRs in severe impact zones.

Tread Design Innovations

The OTR patterns of Birla tyres reflect service-specific priorities. For instance, our tread designs with aggressive deep lugs ensure traction on loose rock and unprepared surfaces. Also, the stone ejector geometries on the tyre limit issues, such as drilling and trapping.

Additionally, ribbed hybrids provide directional control and stability for graders and industrial vehicles. Moreover, smooth treads maximize contact area and resist cutting in confined, abrasive underground environments.

Heat and Puncture Resistance

Long duty cycles drive internal heat, especially in thick bias construction. The compounds used on Birla OTRs are engineered to be thermally stable, reducing heat buildup that can cause ply separation.

Additionally, cut-resistant compounds and reinforced casings address sidewall injuries and issues like puncture. The thoughtfully engineered tread compounds of Birla Tyres are efficient in rocky pits or underground headings.

Sustainability in Tyre Technology

Beyond performance, Birla underscores a commitment to sustainability, including exploration of recycled inputs and end-of-life solutions.

The commitment to sustainable operation goes beyond manufacturing. At Birla Tyres, we prioritize ESG (Environmental, Social, and Governance) and address our social responsibility to pave the way toward an eco-friendly future. The principle here is to enhance safety on the road while staying compliant with the environment’s needs.

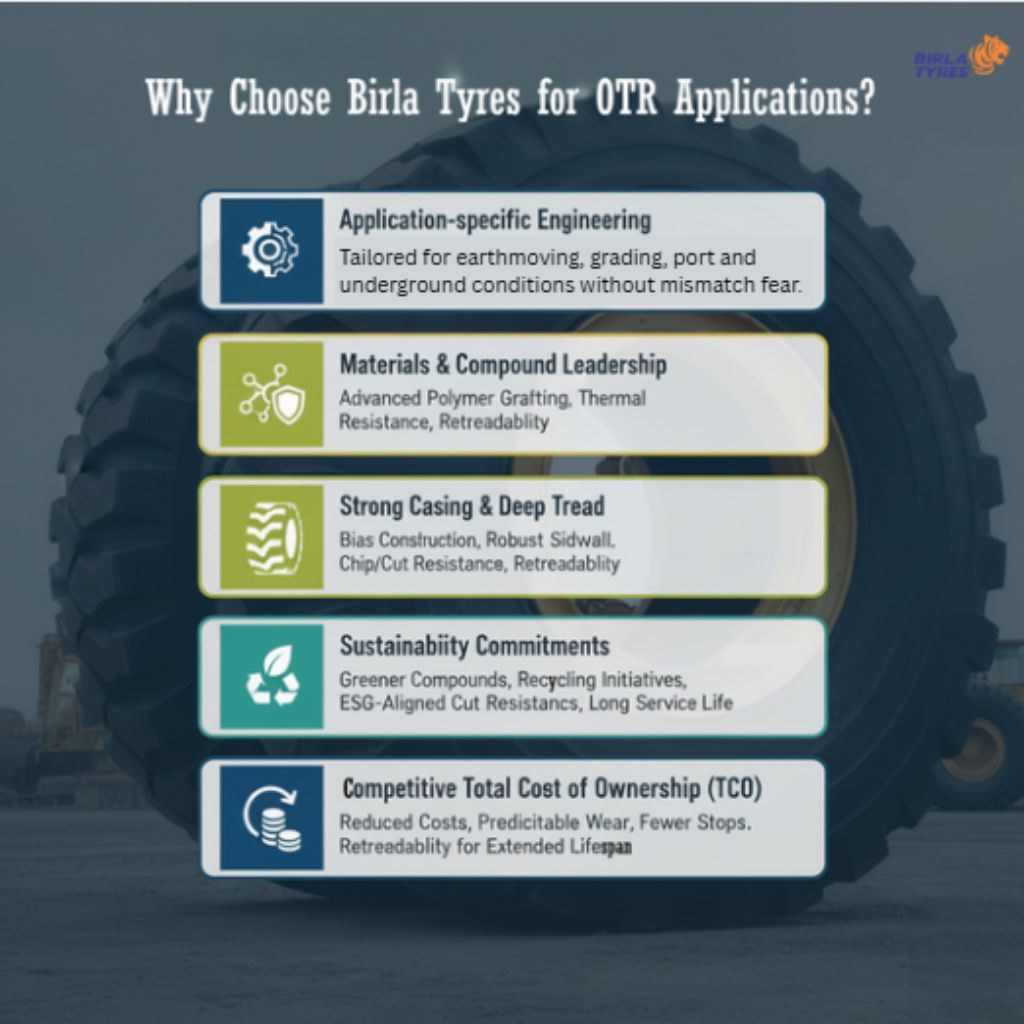

Why Choose Birla Tyres for OTR Applications?

Beyond the science and engineering behind Birla OTRs, we encourage users to prioritize their needs and safety first. However, if you’re second-guessing before choosing any of Birla’s OTRs, let us help you understand why you should take the next step.

Application-specific Engineering

We engineer solutions for earthmoving, grading, port, and underground equipment. Thanks to the varied range of application-specific tyres, there’s no fear of mismatching tyres.

Materials and Compound Leadership

Polymer grafting and additive packages target durability, thermal resistance, and retreadability as primary benefits for off-road tyres.

Strong Casing & Deep Tread

Bias constructions and robust sidewall design ensure that the tyres perform efficiently in high-impact zones. Additionally, service-specific tread depth and chip/cut resistance help users operate easily for a long service life.

Competitive Total Cost of Ownership (TCO)

Going beyond sustainability commitments, with Birla Tyres, the cost of ownership goes down significantly. Durability and uptime translate into predictable wear curves and fewer unscheduled stops. Additionally, the tyres are designed with tetradability in mind. So, users can increase the lifespan of their tyres by retreading on time.

Science that Predicts Safety & Efficiency

OTR environments impose unique demands that only specialized tyre technology can meet: high-load casings, cut-resistant compounds, heat management, and tread designs tailored to the job.

The vast and diverse OTR portfolio of Birla Tyres has a solution for every off-the-road need. The mining-ready Kalapatthar and earthmovers like Ultra Trac are already the first choice of many drivers operating in their respective environments.

Choose Birla Tyres today for robust operations in some of the toughest workplaces on earth!

FAQs

1. What Makes Birla Tyre’s OTR Tyres Suitable for Extreme Environments?

Engineered with advanced compounds, reinforced casings, and cut-resistant tread designs, Birla Tyres has a wide range of OTRs for application-specific needs. Users can rely on Birla’s range of OTRs for mining, construction, and agricultural equipment.

2. How Does Birla Tyre Ensure Durability and Safety in Its OTR Tyres?

Through rigorous testing, precision engineering, and features like sidewall protection, heat-resistant materials, and stone-ejecting tread patterns, Birla Tyre enhances both durability and operational safety.

3. Are Birla’s OTR Tyres Customizable for Specific Industrial Needs?

Yes, Birla Tyres customizes its tyre design and construction specific to different industrial needs. The tyres are designed with different terrains such as construction, agriculture, and harsh mining grounds in mind. Users can also find the machine, size, and load capacity appropriate tyres according to their equipment manufacturer’s instructions.