Mining and High-Heat Applications: Why Industry Counts on Nitrogen

Date: 30 August 2025

In domains like mining and other high-heat industrial operations, factors such as safety, efficiency, and durability are crucial. An underrated, yet vital component in such an environment is the tyre inflation medium.

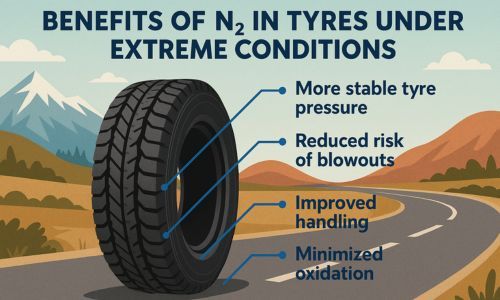

The traditional choice for tyres is compressed air. However, the latest industry practices and evidence from industrial applications suggest that the emphasis is more on the benefits of nitrogen in tyres. Nitrogen offers a series of benefits, suitable for most heavy-duty applications, particularly in extreme conditions.

The Rationale for Nitrogen in Mining Tyres

Mining vehicles, such as haul trucks, loaders, and earthmovers, are prone to operating under significant stress. These commercial vehicles carry tons of materials through rugged terrain and often operate at high altitudes. Therefore, the tyres are subjected to intense pressure, extreme heat, and usually wear and tear.

Compressed air inflation that contains moisture and oxygen in high proportions makes the tyres vulnerable. The major threats to compressed air-inflated truck tyres in these conditions are:

- Rigorous oxidation and speedy corrosion

- Fluctuation in pressure due to temperature changes

- No means of Fire Suppression, rather ignition risks are increased

In sharp contrast, nitrogen is dry and inert. Most importantly, it is stable. Thus, the environment where it is loaded is safer. The stability that it adds to the vehicle tyres is paramount in extreme conditions.

Reducing Fire Breakout and Explosion Risks

One of the main reasons why N2 in commercial vehicle tyres is a good choice is the safety that it adds. Since compressed air contains oxygen that helps in combustion, it is not an ideal choice in extreme conditions. The off-road conditions in mining sites put tremendous pressure on the tyres.

If your tyres are not optimally maintained, you are at risk of a tyre explosion. However, N2 reduces such chances.

Compressed air-inflated tyres in high heat or off-road conditions usually lead to pyrolysis. It is a chemical reaction responsible for releasing flammable gases within tyres. When tyres are struck by lightning or exposed to high heat, the oxygen inside can lead to a catastrophic explosion.

But the question that readers may ask here is how nitrogen averts such risks? When nitrogen-inflated tyres are used, the usual oxygen content inside tyres is around 5% or lower. That significantly reduces the chances of combustion.

The Department of Mines and Petroleum Resources Safety proclaimed that nitrogen tyres with 95% pure N2 are 20% cooler compared to compressed air-inflated tyres.

How N2 Tyres Perform in High Heat Conditions?

There are evident benefits of nitrogen in tyres in high-heat conditions. The foremost benefit is pressure stability, in addition to prolonged tyre life and efficient fuel consumption. The tyre industry also promotes the use of N2 instead of compressed air in high-heat conditions.

Pressure Stability

Nitrogen molecules are larger compared to O2 molecules. Hence, they are less likely to permeate through the tyre rubber. As a result, the pressure loss of tyres is also lower. When aiming to maintain an optimal pressure condition over time, this quality becomes particularly helpful.

In the mining regions, temperature changes are common. The days are scorching, while the nights are usually cooler. Meanwhile, nitrogen is highly temperature-resistant, ensuring consistent pressure and reducing the risk of under-inflation or over-inflation.

Prolonged Tyre Life

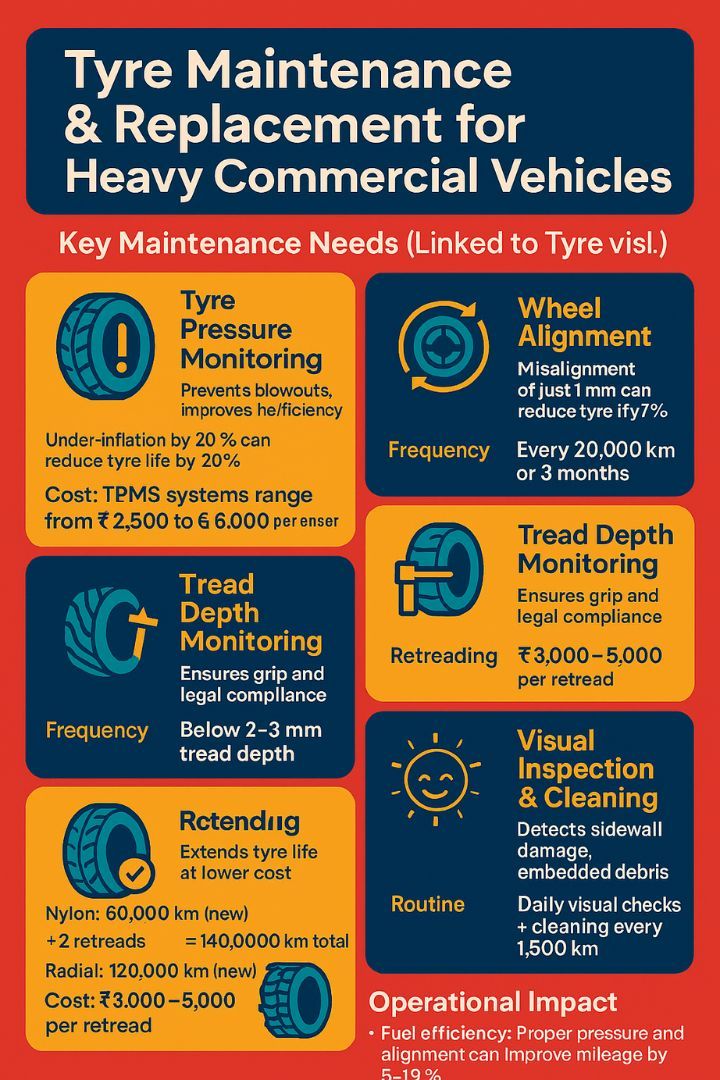

The nitrogen-inflated tyres go through less internal corrosion. The lack of moisture in a dry gas like Nitrogen helps the cause. The reduced corrosion protects steel belts and rims thoroughly. As a result, the overall lifespan of tyres is substantially improved. According to recent studies, nitrogen inflation is capable of extending the lifespan of tyres by more than 10%.

Moreover, the report collected from several fleet operators confirms that nitrogen significantly enhances retread cycles and casing durability. That usually results in a sharp 40% reduction in the tyre management costs. Hence, the use of N2 in tyres is beneficial from an economic point of view too.

Fuel Efficiency

As discussed, fuel efficiency is a key factor for fleet owners of commercial vehicles. On that note, the primary factor affecting fuel efficiency is rolling resistance. Cars with high rolling resistance tend to have low fuel efficiency, and vice versa.

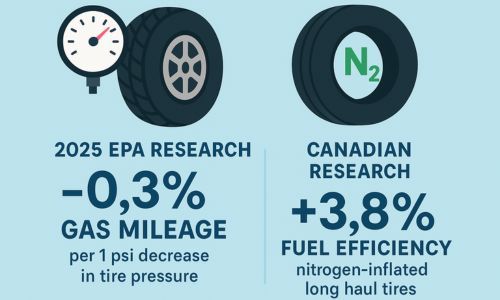

In recent research, the US Environmental Protection Agency projected a drop in gas mileage of around 0.3% for every 1 psi reduction in tyre pressure.

Another research in Canada confirmed that you can achieve a 3.8% boost in your vehicle’s fuel efficiency using nitrogen-inflated tyres. The research suggests that the stat proves more plausible when using N2 in long-haul vehicle tyres.

The Economic and Operating benefits of nitrogen in tyres

Among several benefits, the economic and operating efficiencies are most important. Here are some conspicuous benefits that vehicle owners in heavy industries are especially looking for:

Reduced Downtime

Tyre failure is a crucial factor that usually leads to operational downtime. Nitrogen inflation typically helps maintain an optimal pressure level and significantly reduces flex and friction. These two are the primary causes of overheating and frequent blowouts in rugged conditions.

As a result, issues such as frequent work halts are also reduced. This improves productivity to a considerable level.

Reduced Maintenance Costs

Compressed air adds moisture to tyres. It may lead to substantial rust and corrosion. Typically, rims and internal components are prone to rusting easily. However, N2 is dry.

So, using N2 in tyres reduces the moisture. Thus, your tyre can work optimally without frequent maintenance trips and costly replacements, especially when considering the heavy commercial vehicles we are discussing.

Better Return on Investment

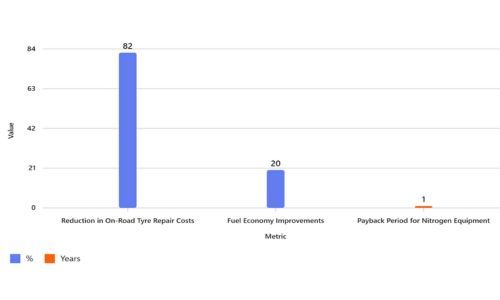

When you invest in nitrogen inflation systems, particularly on-site nitrogen generators, you can yield a credible ROI. According to recent investigations in 2025, an 82% reduction in on-road tyre repair costs is possible when using nitrogen tyres.

N2 can also reduce your fuel expenses by more than 20%. Additionally, the payback period of less than one year applies to nitrogen generation equipment.

Environmental Impact

Nitrogen inflation of tyres is also good for the environment. Firstly, it reduces fuel consumption, which in turn reduces the emission of greenhouse gases. A genuine enabler of environmental sustainability.

In addition, extended tyre life means manufacturing and usage of fewer tyres. Even the count of disposed tyres is reduced. On-site nitrogen generation can help you reduce the carbon footprint linked to transporting bottled nitrogen.

Challenges of Implementation and Relevant Solutions

The benefits of nitrogen in tyres are evident. The implementation of N2 inflation in remote mining regions, however, can cause serious logistical challenges. Transporting bottled nitrogen is costly. Moreover, its environmental effects are also enormous. However, there is an alternative. You can focus on “on-site nitrogen generation”.

The agencies like Gs Generation Australia and Atlas Copco manufacture modular and scalable nitrogen generators. These generators are ready for transportation and installation in selected mining operation centres.

The generators offer:

- The choice to adjust the purity of nitrogen to 98%

- Inbuilt compressors and dryers

- Remote monitoring capabilities

- Relatable Cases of Industry Adoption

Nitrogen inflation is gradually gaining popularity on a global scale. In South Africa, it has become a standard industry practice. Most big mining companies in South Africa now rely on N2-filled tyres.

Organizations like NitraLife offer nitrogen generators to Zambian mines, followed by mines in the Congo, parts of Asia, and the USA. The bottom line is that a prevalent ecosystem of suppliers and adopters exists. Therefore, the commercial scaling of N2 generators is imminent.

Moreover, in Australia, where harsh mining conditions prevail, N2 inflation is profoundly rising. It is a benchmark of mine safety and efficiency.

Key Takeaways

In almost all mining and high-heat applications, tyre performance is paramount. It is not a major performance indicator. It is also a proponent of safety and cost management. Foremostly of sustainability. N2 offers genuine solutions to challenges created by traditional refill, the compressed air.

From reducing fire risks to preventing tyre blasts, the benefits of nitrogen in tyres are endless. N2 inflation also prolongs the tyre lifespan. From an economic standpoint, N2 offers better fuel efficiency, besides reduced maintenance costs. The bottom line is that N2 is gradually becoming an indispensable asset in the whole tyre industry.

Frequently Asked Questions (FAQs)

1. Why is N2 preferred in mining tyre inflation?

N2 plays a key role in resisting heat build-up. It also significantly reduces blowout risks. Thus improving tyre lifetime in the mining and extreme heat conditions.

2. How can N2 assure safety in all high-heat applications?

N2 ensures stable pressure under high-heat conditions. It substantially reduces tyre failure and related risk. In demanding industrial conditions, this is a great leverage.

3. Is N2 inflation cost-effective when it comes to heavy-duty tyres?

It surely reduces maintenance and improves fuel efficiency. Moreover, N2 inflation also offers genuine ROI growth.