Safety First: How Worn Treads Extend Braking Distance

Date: 03 September 2025

Safe driving starts with understanding the safety standards of a vehicle. As a country with extremely populated roads, the number of accidents in India is not going down.

A significant number of these accidents happen due to failure of braking, and increased brake distance on the road is a critical factor causing brake failure.

A 2020 article on Hindustan Times cited that overloading caused 8% of the crashes on the road. Overloading increases the kinetic energy of a vehicle, making it require a longer braking distance to stop. Additionally, overloading also causes the tyre tread to wear out fast, increasing the braking distance in the process.

We have observed how tyre tread wear indicators are connected to increased braking distance, affecting safety on the road. Go through this article to know how worn-out tyre treads can be dangerous for you and how to spot them.

What Are Tyre Treads & Why Do They Matter for Improved Braking Distance?

The dense foundation of rubber tyres has patterned sections on the surface. These patterns serve more than visual appeal on the tyre.

These patterns, called tread pattern engineering, are the key portions of the tyre that contact the road. In doing so, the patterns help the tyre get good grip and traction on the road.

There are multiple components to a tread pattern tyre design, and it consists of

Tread Blocks: These are the raised rubber segments that help get a strong grip on the road by forming the primary contact with the road. Tread blocks also play a critical role in breaking and acceleration.

Ribs: Segmented or continuous bands of blocks running around the circumference of the tyre.

Grooves: Deep channels running laterally and through the circumference of the tyre are called grooves. These sections of the tread pattern design ensure that water easily evacuates from the patches of the tyre. Therefore, these components are essential for the tyre’s cooling.

Sipes: These are the thin slits and slots molded inside the tyre’s tread blocks. These components create additional biting edges. Consequently, they help get better traction against snowy and wet roads.

Why does Tyre Treads Matter?

Tyre treads play key roles in safeguarding a vehicle’s performance on the road. It helps a vehicle navigate different types of roads and road conditions while also avoiding risky situations like accidents.

Braking & Tractions: Treads and grooves play a critical role in creating a friction between the road and the tyre, supporting safe acceleration, braking, and steering—especially when driving on a rough or wet road.

Water Expulsion: Grooves and channels help in pushing the water away from the contact area between the road and the tyre. Thereby, it helps the tyre prevent conditions such as hydroplaning.

Heat Management: Tread patterns are also essential in dissipating heat produced when driving. In fact, the tread patterns are the primary tyre tread wear indicators signalling whether there’s a need for changing tyres or not.

Noise Reduction: The spacing, shape, and pitch of the tread block tyres reduce road noise. It contributes to a smoother and quieter riding experience.

The function of a strong grip, improved traction, and expulsion of water at the contact point between the road and the tyre surface improves braking distance.

However, it’s critical to understand how braking works before decoding why treads extend braking distance.

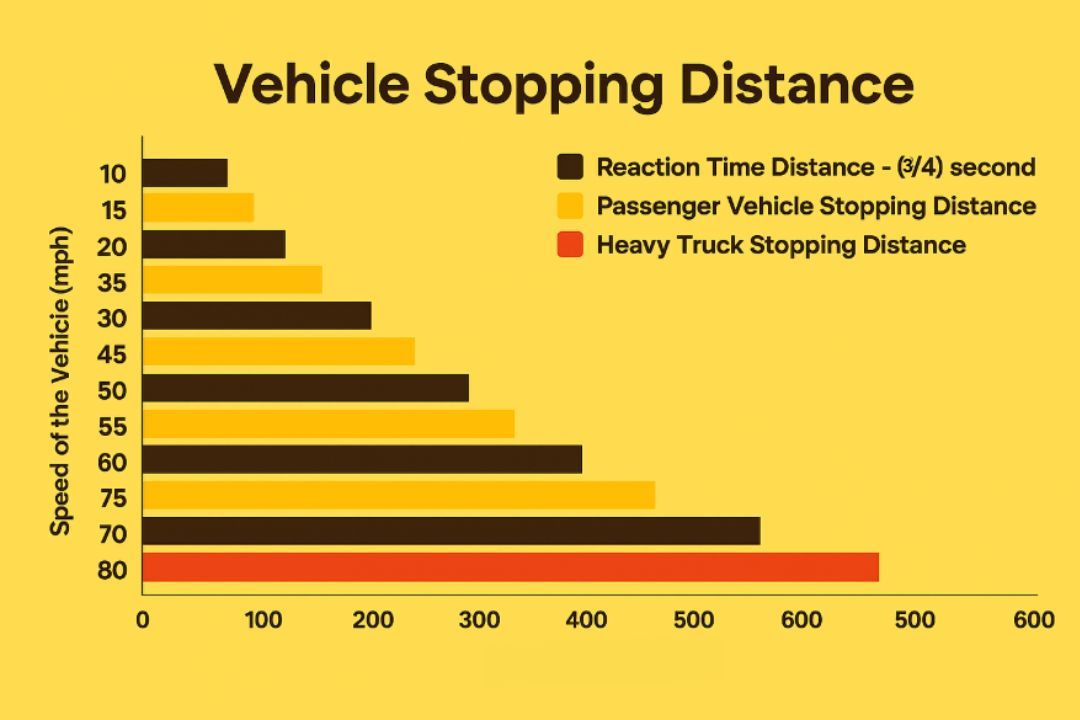

The Science Behind Braking Distance

There's a common misconception around breaking distance. According to many, doubling the speed doubles the braking distance. Additionally, some think that anti-lock braking systems (ABS) shorten the braking distance.

In reality, calculating braking distance requires an understanding of the reaction time, braking distance, and stopping distance.

Here's a breakdown:

Reaction Time: Reaction time helps a driver perceive a hazard and choose to use the brake.

Reaction Distance: The reaction distance is the distance the vehicle covers before choosing to apply the brake and applying it.

Braking Distance: Braking distance means the distance the vehicle covers between the moment the driver applies the brake and comes to a stop.

Stopping Distance: The stopping distance covers the range from perceiving the hazard till the vehicle comes to a halt.

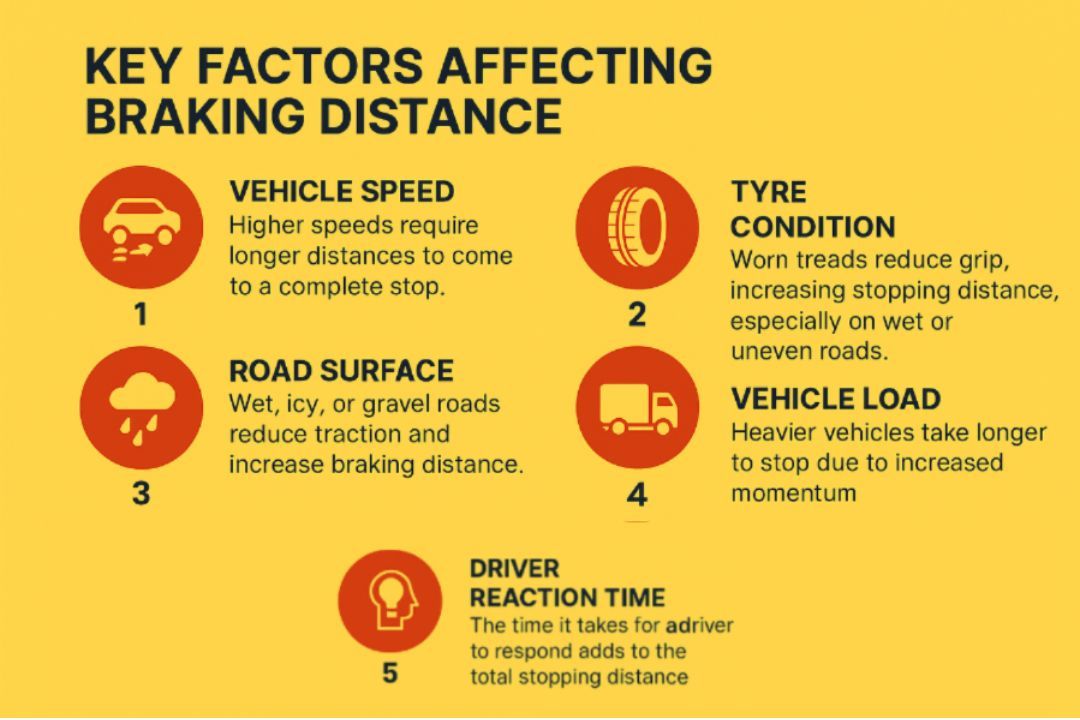

Key Factors Affecting Braking Distance

Multiple factors affect the braking distance:

Speed: Increased speed dramatically increases braking distance.

Worn tyres: Worn treads on tyres affect the braking distance significantly due to reduced friction on the road in the absence of substantial treads.

Brake Condition: Worn-out brake pads, rotors, and other components of the brakes also affect the braking distance. If the braking components are damaged and aren't working properly, it will automatically increase the braking time.

Road Surface & Conditions: The condition of the road, whether wet, icy, muddy, or rough, has immense effects on how the road works.

Vehicle Weight: A heavier vehicle usually has more kinetic energy, therefore takes a longer time to stop.

How Worn Treads Increase Braking Distance?

Tyre tread wear indicators are small raised bars of rubber within the tyre grooves. Once the treads of the tyre wear down to the same level as the tyre tread wear indicators, it's completely worn out. This is also a sign for the vehicle owner to change the tyre's indicator.

The legal tread depth for a truck tyre is 1.6 mm. Anything below the legal limit is unsafe for a vehicle. However, for off-road conditions, experts recommend deeper tread depth. While for optimal performance, you can change tyres around 3 mm depth, for off-road use, try to change tyres much earlier.

Vehicle owners must check the sidewall of their vehicle tyres for the TWI symbol. The symbol points out the location of the indicator and the grooves.

When the tyre treads reduce below the tyre tread wear indicator, it increases the braking distance. Here's how the wearing of the tyre tread affects the braking distance:

Reduced Traction

The tyre treads are like thousands of tiny hands that help the tyre get a grip on the road. But when the tyre treads wear out, it makes the vehicle lose traction. As a result, reduced grip translates into increased braking distance.

Water Evacuation

The tyre treads have another major function. These are responsible for channeling the water away from the road surface. This feature enables the vehicle to tread on to the road instead of floating on top of the water layer. It's highly important for stopping the vehicle from hydroplaning.

Hardened Rubber

Tyre rubber becomes harder over time. It typically increases the contract area and reduces the overall flexibility and grip of the hard rubber. It negatively affects the overall ability of the vehicle to stick to the ground, thereby increasing the braking distance.

Why Does Tyre Tread Wear Indicator Matter in India?

Worn tyres are regulated under the Motor Vehicle Act and the Hazardous and Other Wastes Rules 2016.

For two-wheeler vehicles, 0.8 mm is the minimum level of tyre tread depth, whereas for other motor vehicles, including truck bus tyres, the less than 1.6 mm Non-Skid Depth (NSD) is unsafe.

In addition, the Extended Producer Responsibility Frameworks have mandates for manufacturers to improve and manage the end-of-life responsibly. Not adhering to the limit for tyre tread wear indicators can cause legal penalties for the drivers. In the worst case, worn-out tyres increase braking distance and cause accidents.

Impact on Indian Roads

Tread pattern reduction on the tyres matters for the Indian roads. Here's why:

- India experiences heavy rainfall during the monsoon. Without tread pattern designs, vehicles have a higher chance of hydroplaning.

- Roads in India are challenging. Puddles, debris, and other hazards are often visible on the road. Reduction of the tread pattern on the tyre causes the vehicle to lose traction.

- Driver safety gets compromised and affected if the tread pattern designs are reduced. Especially, vehicles with an anti-lock braking system can get overwhelmed when the tyres have reduced grip on the road.

How to Check Tread Wear?

Coming to the solution, here's how you can ensure the safety of your vehicle through timely check of the tread wear indicators:

Step 1: Locate the TWIs

Start by locating the tyre tread wear indicators. These are small, raised rubber bars placed in the tread grooves. You'll find them around the circumference of the tyre.

Step 2: Examine the indicators

Check if the tyre treads have come down to the level of the indicators.

Step 3: Replace

If the tyre tread goes below the limit of the tyre tread indicator (preferably 1.6 mm and below), then it's time to replace it.

Popular Tip: Many vehicle owners typically use a two-rupee coin and insert it inside the tyre's groove. If the coin is fully submerged, then it means that the tyre is still usable. But if the coin shows on the surface, it's time to change it.

Replace Your Tyre Before it's too Late

While there are different ways to maintain the tread depth of your tyre, it will eventually wear out. What's more important is to know when exactly your vehicle needs a change of tyres.

The correlation between tyre tread depth and the braking distance is evident. This article rightly points out why you must pay attention to the wearing out of the tread depth.

We at Birla Tyres ensure that the tyres on your vehicles are compliant with the regulatory and safety standards. The quality standards followed for the Birla tyres also ensure your vehicle gets a better grip on the road and has efficient water drainage capabilities.

Use the tread wear check procedures provided here to decide whether it's time to change your vehicle tyres. Check out our truck bus bias tyres to get the best quality product.

Frequently Asked Questions

What Depth are Tyre Tread Indicators?

A: Tread Wear Indicators, or TWI, are tiny raised bars of rubber. These bars typically stay inside the grooves of the tread pattern design. When the tyre tread design wears down to its limit, it indicates the wear of the tyre.

Is 2.5 mm Tyre Tread ok?

A: This is the indicator that the tyre has worn out and lost its effectiveness. But, you can still continue to use the tyre till it reaches 1.6 mm of tread depth. However, it would be a wise decision to change your tyre at a 3 mm tread depth for safety on off-roading conditions.

How to Check Tread Wear Indicators?

A: Typically, you can measure if the tyre tread designs have reached the indicators (as mentioned on the sidelines of the tyre. You can also use a two-rupee coin and place it in the middle of the tyre’s grooves and see if it shows on the surface. If it shows on the surface, you must change the tyre at the earliest.