Why Bulges Are Fatal: Understanding Bias Tyre Sidewall Failures

Date: 15 September 2025

Tyre bulges are the silent threat to commercial fleets and vehicles used for construction works.

Ignoring slight bulges can cause tyre sidewall damage, turning a high investment and critical infrastructure into liabilities almost overnight.

In most cases, tyre bulges are difficult to spot. However, if you look closely, you’ll find it lurking on the bias ply sidewall of the tyre.

We have addressed how bulges on tyres can lead to fatal accidents, causing serious damage, and why you should not overlook one.

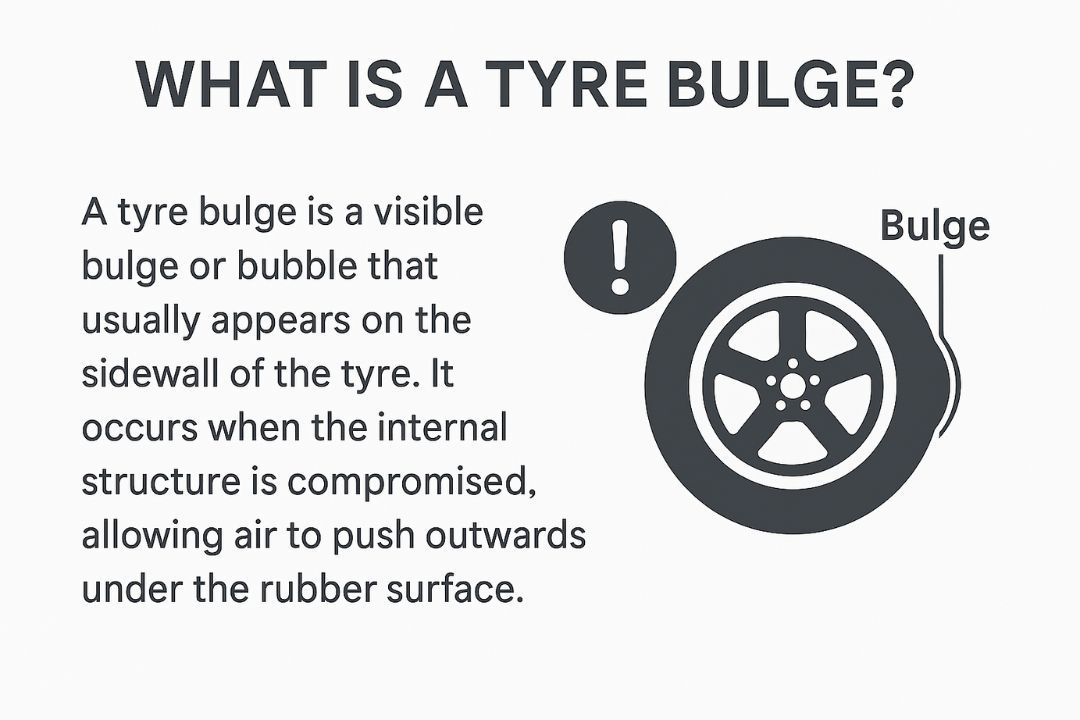

What is a Tyre Bulge?

What it means: A tyre bulge is a visible swelling or lump on the tyre. It’s a bubble visible on the tyre surface caused by the air that escaped the inner liner of the tyre. Typically found on the sidewalls of the tyre, a tyre bulge signals internal damage.

What it causes: It also indicates that the overuse of such tyres can lead to fatal accidents, especially for heavy-duty commercial vehicles that handle significant weight.

Internal structure failure, impact trauma from road potholes or curbs, and underinflation are among the most common reasons that damage the inner liner of the tyre. Such damages make the air inside the inner liners escape and reach the surface of the sidewalls.

How a tyre bulge appears: The sidewalls of the tyre, which protect the inner plies and cords, absorb the stress of the rough surfaces and the impact on the road, and are the final surface for the escaped air. Eventually, the air creates bulges on the tyre surface.

The bulges aren’t capable of withstanding normal driving stresses, and they are highly susceptible to burst, blowout, and catastrophic failure. Heavy-duty vehicles with tyre bulges are at a fatal danger of losing control and facing a serious accident.

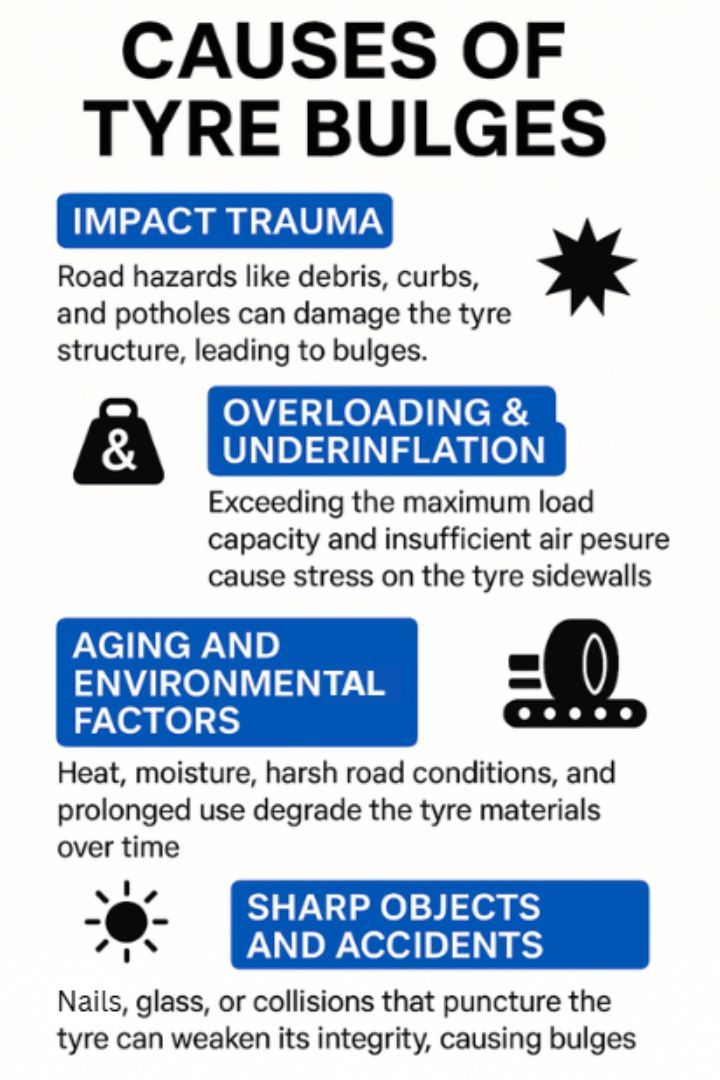

Causes of Tyre Bulges

The following are the major reasons that cause tyre bulges:

1. Impact Trauma

Impact trauma is the major reason for tyre bulges due to tyre sidewall damage. Road hazards are critical culprits behind bulges.

Striking debris, curbs, speed bumps, and potholes on hazardous roads cause significant damage to the tyre’s internal parts. It can eventually lead the air inside the inner plies to the surface of the tyre sidewall.

Constant damage to the tyre causes microfractures on the inside of the tyre. It results in localized internal delamination and air seepage.

Excessive load accumulation and off-road activities of commercial and construction-related vehicles lead to significant damage to the tyre sidewalls.

As a solution, off-road and commercial vehicles can use bias ply technology and quality control essential for managing damage.

2. Overloading & Underinflation

Stress on tyres typically comes due to constantly overloading a vehicle and exceeding the maximum weight-bearing capacity. Furthermore, under-inflated tyres struggle to handle the impact of debris and hazards on the road.

Underinflation causes stress on the tyre sidewalls, accelerates fatigue, and causes the adhesive to fail at the rubber-cord interface. When the stress accumulates, cracks start to form. Eventually, it paves the way for bulges and eventual blowouts.

3. Aging and Environmental Factors

Tyres are prone to decay and damage. Continuous use for a long time causes the adhesives to degrade. Exposure to heat, moisture, chemicals, and difficult road conditions reduces the bonding strength in the tyre component.

Eventually, when the components of the tyre lose their bonding, it causes subsequent bulge formation. Typically, exposure to harsh climates, vibrations, and standing loads are the primary reasons for aging tyres to lose formation strength.

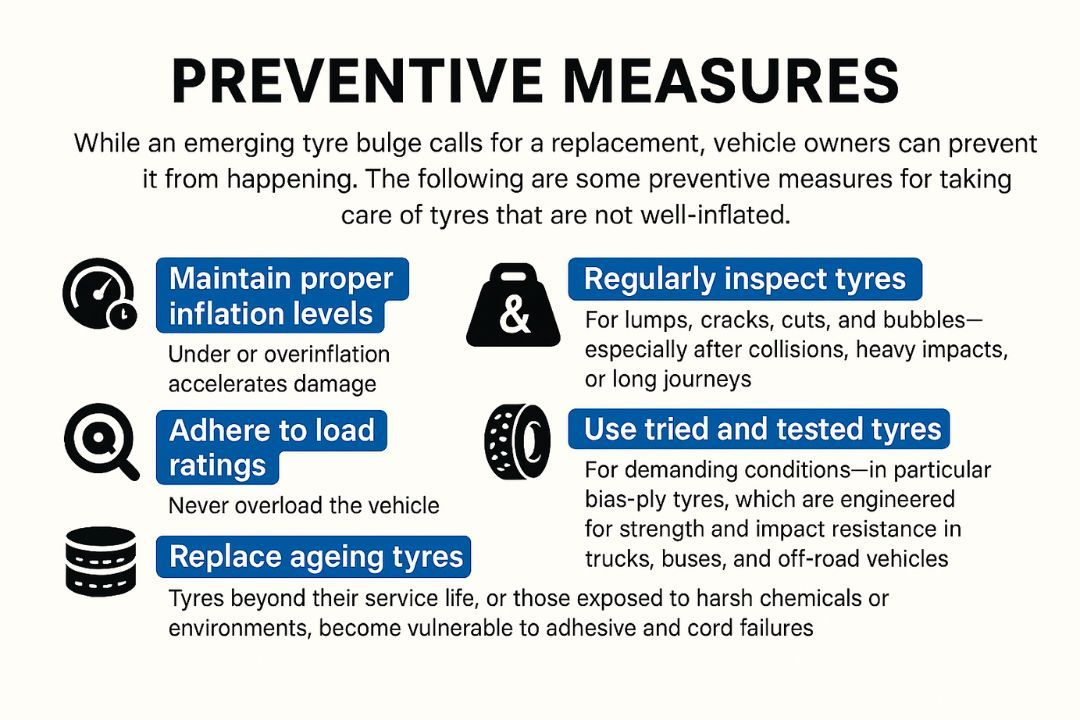

As a protective measure, drivers and vehicle owners must constantly inspect the tyre health and schedule maintenance and replacement accordingly.

4. Sharp Objects and Accidents

Sharp objects on the road also affect the health of the tyre. Nails, glass, and accidents can cause the tyre to puncture. Frequent punctures and repairs create weak spots inside the tyre.

This is also among the common reasons for the air to escape to the outer surface of the tyre’s sidewall. Damages due to sharp objects make the tyre vulnerable and risk sudden failure on the road.

Why are Bulges a Major Problem for Commercial, Constructional, and Agricultural Vehicles?

Here are the reasons why bulges can lead to fatal problems for commercial vehicles:

Imminent Catastrophic Failure

Fleet owners and drivers of commercial or construction-related vehicles must respond to any bulge appearing on the tyre. Even a minimal tyre sidewall damage can lead to sidewall blowout due to growing internal pressure—especially when the vehicle is on the move.

Tyre blowouts make the vehicle lose control, leading to a fatal accident. Especially for trucks and construction vehicles driving at high speeds or hauling loads, they can face rollover or severe accidents.

Safety Hazards and Downtime

A single accident or on-road tyre blowout due to tyre bulges can lead to multiple co-occurring accidents. Eventually, it can damage cargo on transport or infrastructure.

Furthermore, the accident causes injuries to the people involved. The cost of infrastructure repair, legal hurdles, repairs, and loss of productivity leads to significant loss.

Irrecoverable Damage

Unlike the tread pattern damage, tyre bulges make the tyre disintegrate from the inside out. The entire structure of the tyre gets compromised, leaving it with only one solution—replacement of the tyre. Vehicle owners also must know that attempting to repair tyre bulges can lead to injuries of severe financial loses.

Financial and Operational Losses

The downtimes caused by accidents due to a lack of attention to the tyre’s health cause operational losses. Unplanned business downtime can paralyze the supply chain.

It also affects construction projects. Additionally, costs are escalating for emergency maintenance and insurance claims, which pile on top of the financial loss already incurred during the accident.

How to Respond When You Spot a Bulge?

Avoid tyre sidewall damage by spotting a tyre bulge at the earliest. It’s best to start by identifying the problem at its root. Here are key things to remember if you are able to spot a bulge on the tyre sidewalls:

Stop and Inspect

Don’t drive further on a bulged tyre. If you have a spare tyre and the tools to replace it, it’s best to replace it immediately. However, we recommend getting help from a professional technician to get it looked at.

They can help you spot similar instances on other tyres as well —just to be on the safer side.

Preventive Measures

Professional Replacement

Tyres displaying sidewall bulges require replacement at the earliest. There’s no way to patch it up or repair the bulges.

Commercial fleets and vehicles can get their tyres checked for bulges and similar damage and get a suitable replacement.

The Science Behind Sidewall Failures: What Research Reveals

Tyre bulges typically originate at the cord-rubber interface. This is where adhesive aging and debonding kickstart propagation and crack initiation.

Several Shearography and X-ray analyses confirm that the outer rubber remains stable chemically. However, the adhesive layer bonds degrade over time because of aging, stress, and heat.

When the adhesive weakens, the cords bearing the load of the vehicle get separated from the surrounding rubber. Eventually, the process creates burst points over time. So, when the tyre gets inflated or handles a significant level of pressure, it results in sidewall failures.

Birla Tyres: Setting the Prime Standard

Birla Tyres is gearing up to become a strong player in the commercial vehicle tyre segment, specializing in truck, bus, and agricultural bias ply technologies, precisely engineered for x, impact resistance, and minimal sidewall failure.

Capable products like an advanced truck tyre use durable plies, advanced compounds, and superior adhesive bonding, reducing the chances of tyre bulges by a significant margin.

The chances for structural failure or loss of adhesive, creating bursting points, are very low with the commercial-grade vehicle tyres.

As commercial operations grow in complexity and scale, our range of products brings the solution to decade-long issues such as tyre bulges on bias ply sidewalls. We empower commercial vehicles to operate with safe, durable, and high-standard tyres that focus on safety.

We recommend that drivers and fleet operators recognize tyre bulges as a significant safety hazard and proactively seek out solutions. Your choice and priority can secure productivity, save lives, and set you up for long-term success.

FAQs

Is it Safe to Drive on a Tyre with a Bulge?

A: It is extremely dangerous to drive with a tyre bulge. Tyre bulges can cause tyre sidewall damage and blowout on the road. It can lead to loss of vehicle control and cause serious accidents.

How long can I drive with a tyre Bulge?

A: Experts recommend not driving even a single mile when you have a tyre bulge on the tyre’s sidewall. Bulges indicate serious structural damage and can potentially lead to accidents.

Is it better to replace a tyre with a Bulge?

A: Yes, you must replace a tyre with a bulge at the earliest. Remember, there’s no way to repair a tyre that has a bulge. Also, attempting to repair a tyre with a bulge can lead to fatalities since tyre bulge repairing isn’t recommended.