Decoding Truck Tyre Treads: How do Tyre Tread Patterns Impact Traction, & Wear

Date: 28 October 2025

Truck tyres have a more significant role than simply providing mobility on the road. They form a strong grip on the road, endure harsh road conditions, and adapt to the changing natures of different terrains. Tyre tread patterns are the foundation of these abilities of tyres. They can directly influence wear resistance and improve traction.

Whether your vehicle is hitting the highway or navigating rugged terrains, the right tyre tread patterns make all the difference in performance. Behind the carefully designed tread patterns, there's efficient engineering impacting the traction and longevity of the tyre.

We have explained how tread pattern designs improve truck tyres' traction and wear resistance.

Understanding Tyre Tread Patterns

Tyre tread patterns are the foundation of safety on the road. These are the bits or the treads on the tyre's surface that build contact with the road. It features patterns of ribs, grooves, and tread blocks to provide a strong grip on the road, ensure traction, and channel water.

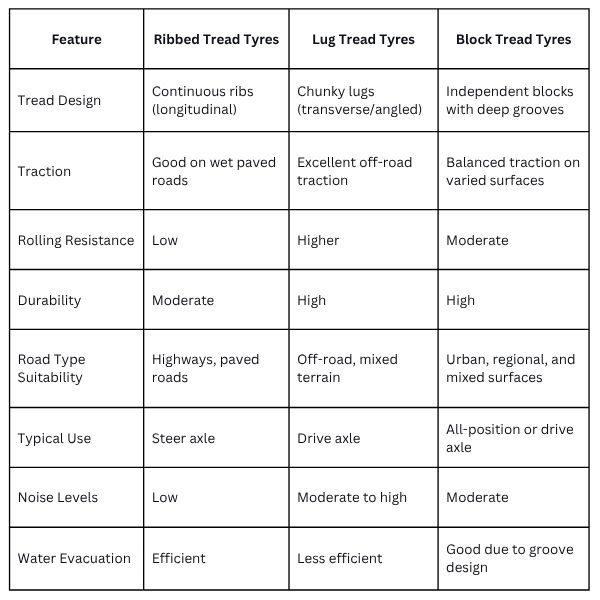

In general, these tread patterns come in three types: symmetrical, asymmetrical, and directional. They play a critical role in distinguishing between different types of truck tyres. However, when it comes to tread pattern designs for tyres, the tread patterns look something like this:

Ribbed Treads

This is a tread pattern design that follows a continuous pattern of parallel grooves running circumferentially around the tyre. Such patterns provide a strong grip and stability on the road, helping the vehicle with better handling, especially when it's on the highway. It's typically visible on free-rolling wheels, and semi-truck tyres.

Lug Treads

This tyre tread pattern design for trucks features large, raised blocks, known as lugs. These are placed across the tyre's circumference to help the trucks with proper traction on paved roads and dirt surfaces.

Furthermore, this tread pattern design helps with a stronger grip. This design is ideal for off-road vehicles and drive axles on roads where high grip is a must. Lug tread pattern is more performance optimized, as you can use them for off-road as well as mixed terrains.

Meanwhile, ribbed tyres offer excellent driveability on highways and paved roads. Both are considered among the best commercial options, but for different operational needs.

Block Treads

This tread pattern design is for mixed surfaces. Typically, this design features large blocks of rubber placed independently across the tyre. The blocks of rubber are separated using grooves.

This tread pattern design is efficient for taking heavy loads, providing strong traction, and high performance on muddy and soft roads. Such tread pattern designs for truck tyres allow better off-road performance.

Each tread pattern design follows a unique tread pattern geometry to influence the traction and braking of the tyre. All three types of truck tyre tread patterns are designed with different levels of stability, resistance, and durability in mind.

The Engineering Behind Tyre Tread Patterns

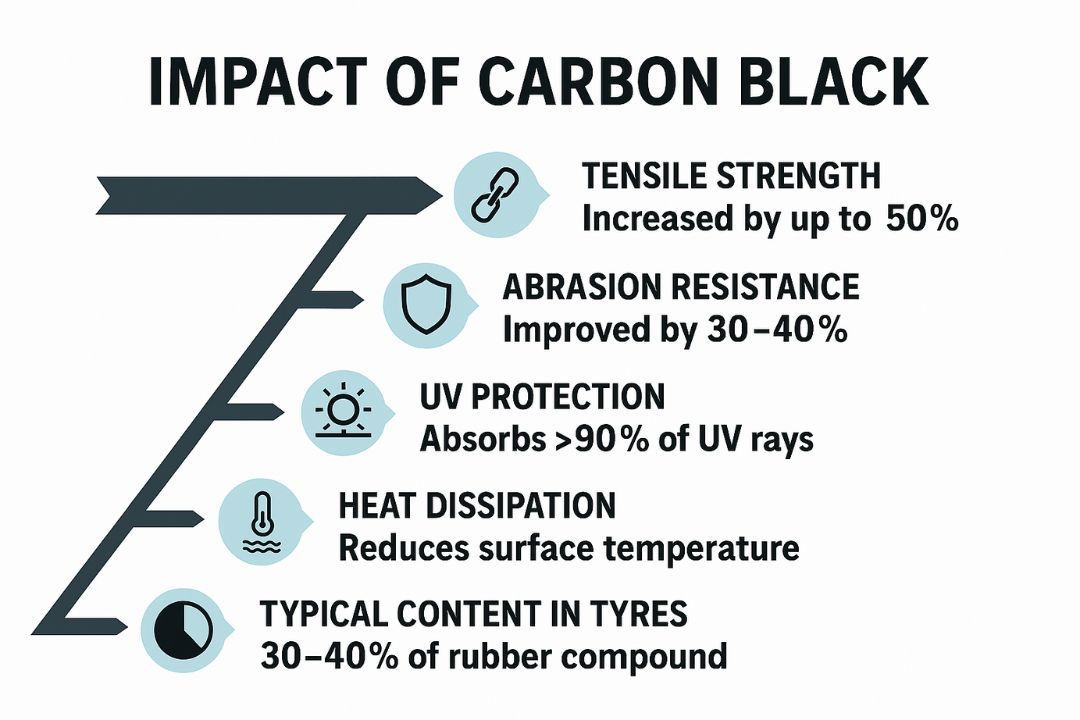

From the design aesthetics of each tread pattern (ribs, tread blocks, grooves, and sipes) to the use of carbon black as the material, engineering is prominent everywhere.

Material Science

Tread rubber compound is composed of blend of NR and synthetic rubber reinforced by high surface area carbon black in commercial vehicle to provide max. milage and good cut and chip resistance.

Passenger car tread compound is made out of synthetic rubber and silica silane filler system to provide good wet and dry traction and breaking.

Structural Design

The structural design of tyre tread patterns ensures the overall stiffness of the tread, its flexibility, and its ability to interact with different materials on the street. The sipes and the grooves of the tyre tread pattern improve water evacuation, handling, and grip.

Structural elements, such as the arch-structured groove walls, improve stability and performance on different terrains.

Simulation & Testing

Simulations and testing of tyres on different conditions are essential parts of tread pattern engineering for a road. Birla Tyres’ R&D team uses CAD modelling for visually designing the tread patterns.

Additionally, 3D modelling has become increasingly prominent in product prototyping. Finite Element Analysis (FEA) enables manufacturers to predict a tyre's performance, including grip and noise levels.

Traction: Engineered for Control

Tyre tread patterns engineer a truck's wheel for better grip, control, traction, and efficiency on wet, gravel, and dry roads.

Symmetrical Tread Patterns: This type of tyre tread pattern provides balanced performance on mildly wet roads. It offers stable handling and low rolling resistance.

Asymmetrical Treads: This type of tread pattern design features different designs on the inside and the outer halves of the tyre. It offers stable handling on wet roads and a low rolling resistance.

Directional Treads: This tread pattern features V-shaped or arrow patterns on the truck tyre to improve channeling of water. The tread's design, including depth, block size, groove patterns, and sipes, has a significant impact on the tyre's traction. It helps ensure channeling of mud and ensures proper contact with the road surface.

Roles of Tread Void Ratio and Grooves

Tread void ratio and grooves play a critical role in enhancing traction and providing an effective biting edge on surfaces such as snow and dirt. These components of tyre tread patterns also contribute significantly to water evacuation and help to prevent hydroplaning.

The balance between voids and rubber contact area with the road surface is essential for maintaining optimal traction performance and wear.

Wear Resistance: Engineered for Longevity

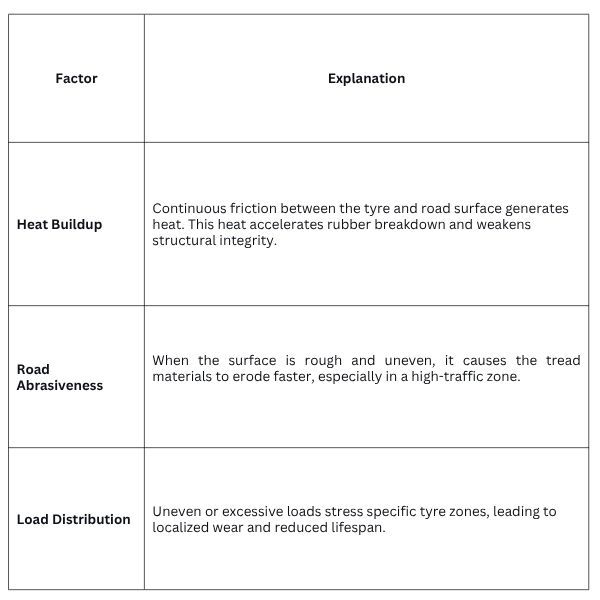

While tyre tread patterns ensure safety, performance, and protection of a vehicle, it doesn't mean that they are immune to decay and wear. Due to heavy use under high loads and demanding conditions, truck tire treads naturally degrade over time, making regular maintenance crucial for safety and operational efficiency. Most common reasons contributing to tread pattern wear include:

Tyre manufacturers use tyre tread pattern engineering to prevent a fast degradation of the tread patterns. The following are the essential tread pattern engineering features to slow down the wearing:

Reinforced Shoulder Blocks: These provide efficient structural support in areas with high stressors. It minimizes the deformation of the tyre and enhances the tyre’s durability.

Heat-Dissipating Tread Designs: Special grooves and patterns improve airflow and reduce heat retention, thereby preserving the quality of the rubber.

Optimized Tread Depth: A carefully calibrated tread depth is essential to balance grip longevity and ensure consistent performance of the tyre over time.

Birla Tyres’ Approach to Wear Resistance & Longevity

At Birla Tyres, wear resistance is one of the threshold features of the tyres we manufacture. Our R&D team’s precise engineering and high-octane innovations deliver advanced tyre architecture. We design our tyres with:

- Robust shoulder architecture, which defies heat from piling up in tyres and keeps abrasion in check, too. In heavy-duty conditions like mining and construction, these qualities become quintessential.

- Advanced Tread Compounds, crafted to improve durability while retaining advanced flexibility and grip.

Birla Tyres optimizes tread geometry and tyre material composition to ensure:

- Longer tyre life

- Seamless and consistent traction

- Convenient driving

These qualities are apparent in tyre ranges like Birla BT 446, specifically engineered for long-haul performance and driving on mixed terrains.

The tyres feature deep tread blocks, heat-resistant compounds, and reinforced sidewalls, making them ideal in the Indian conditions.

Sustainability Considerations in Tread Design

Advanced tread engineering plays a critical role in improving fuel efficiency. When a tyre has a lowered rolling resistance, it requires very minimal energy to move, reducing fuel consumption and improving efficiency. That’s why tread pattern engineering contributes to more than efficiency; it helps develop sustainable vehicles.

Additionally, slow wearing of the tyre tread patterns leads to fewer tyre replacements, meaning less rubber waste and reduced consumption of the tyre’s life. Additionally, when single-vehicle and fleet owners dispose of fewer worn-out tyres, they help reduce their carbon footprint, positively impacting the environment in the process.

Birla Tyres is committed to building sustainable tyre tread patterns that impact beyond resistance to wear and improved traction. We commit to making tyres sustainable, having a prolonged life, and ensuring efficient grip on the road with a smooth and safe riding experience.

FAQs

What is the Main Function of the Tread Pattern on a Tyre?

Tyre tread patterns exist to provide grip for control and traction on the road. The grooves and the sipes of the tyre also help in evacuating water from the contact patch.

How does Tyre Tread Pattern Improve Traction?

Tyre tread patterns come in different types (symmetrical, asymmetrical, and directional). These patterns help the vehicle maintain traction on the road, channel water away from the contact path, and stop issues such as hydroplaning from affecting the vehicles.

Which Tyre Tread Pattern is Best for Trucks?

A truck needs different types of tread pattern designs depending on its intended use. Drivers get the off-road traction from Lug or Deep tread patterns, Rib-Lug hybrids for improved and balanced performance on mixed surfaces.

Additionally, sometimes there are specific steering (F/Z) and Drive (D/Z) patterns for specific axle positions.