Extending Tyre Life: Maintenance Tips for Your OTR Tyres

Date: 14 November 2025

Off-the-road tyre maintenance should not be your 2nd priority as those are not ‘nice-to-have’ products.

Here’s why: Off-the-road tyres are the silent protectors for mining trucks, loaders, graders, port equipment, and farm machinery. They carry significant loads, absorb sharp and heavy impacts, and keep off-road operations moving in heat-intensive and abrasive environments.

A single tyre failure can halt shifts, disrupt productivity, and jeopardise safety. That’s why maximising OTR tyre life is no longer an initiative for improving cost efficiency but a mandate to business efficiency and safety.

As a leading manufacturer of India’s most durable and efficient off-the-road tyres, we shared some tips to follow for maximising your tyres’ life.

Understand Your OTR Tyres

Off-road tyres are durable, have deep tread patterns, and puncture and cut-resistant features. The bias ply construction with its diagonal or criss‑cross plies (≈30–40°) forms the right combination to build the right foundation for OTR tyres.

In fact, the bias ply construction is the ideal for off-road tyres as its flexible sidewalls are capable of handling loads and providing stability on harsh road conditions.

Core Components of Bias OTR Tyres

Off-the-road tyres built using bias construction rely on the following components:

- Tread pattern

- Compound (whether wear, heat, or cut resistant)

- Casing strength

These components collectively ensure cut-resistance, traction, and the tyre’s durability.

9 OTR Tyre Maintenance Tips to Maximise Life Cycle

Follow these practices to maximise your off the road tyres’ lifecycle:

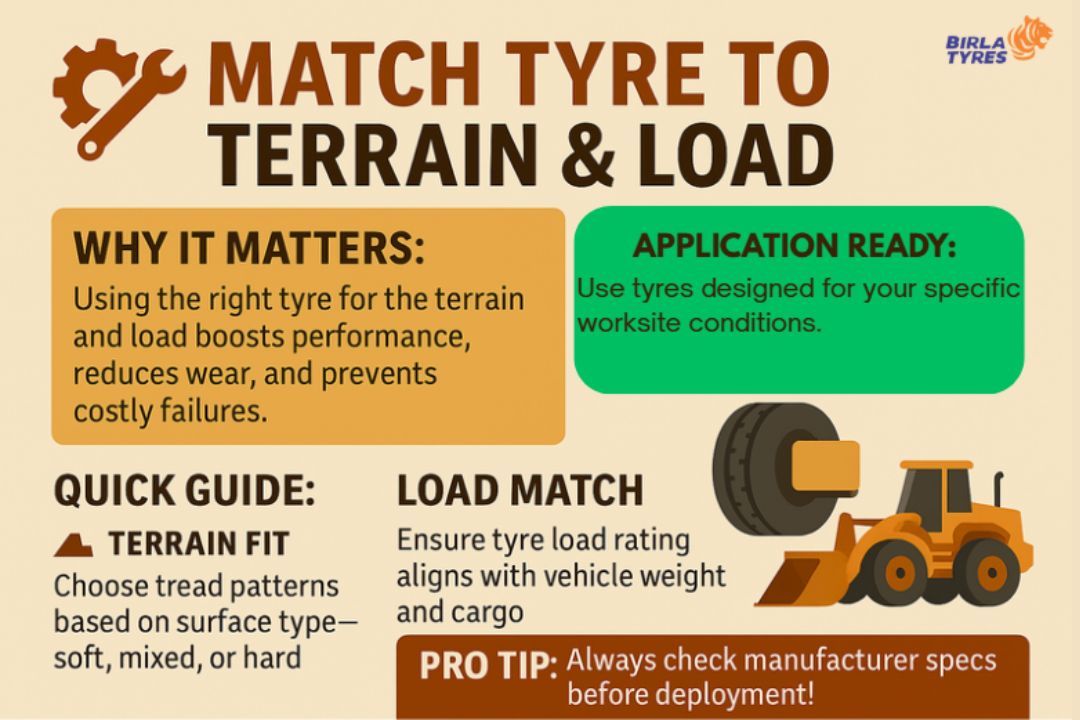

1. Match Tyre to Terrain & Load

Start by understanding the site’s condition and the payload the vehicle is supposed to carry. Then, accordingly, decide on your off-road vehicle OTR tyre.

Birla Tyres uses TRA codes like L-3/L-5 for loaders and E-3/E-4 for earth movers, indicating tread depth and pattern suited to rocky or mixed surfaces.

2. Maintain Correct Inflation

Inflation is directly connected to the tyre’s safety, fuel efficiency, and tyre performance. While over-inflation reduces the tyre’s contact patch, impact resistance, and traction, under-inflation reduces traction.

Things to Avoid:

- Avoid under-inflation: Excessive flex leads to increased heat build-up, causes ply-belt damage, and premature failure.

- Avoid over-inflation: higher wear rates, reduced traction, and more cuts or impact breaks.

Uncertain whether you're caring for your tyres correctly? Check out our blog: Top Tyre Maintenance Tips Every Vehicle Owner Should Know

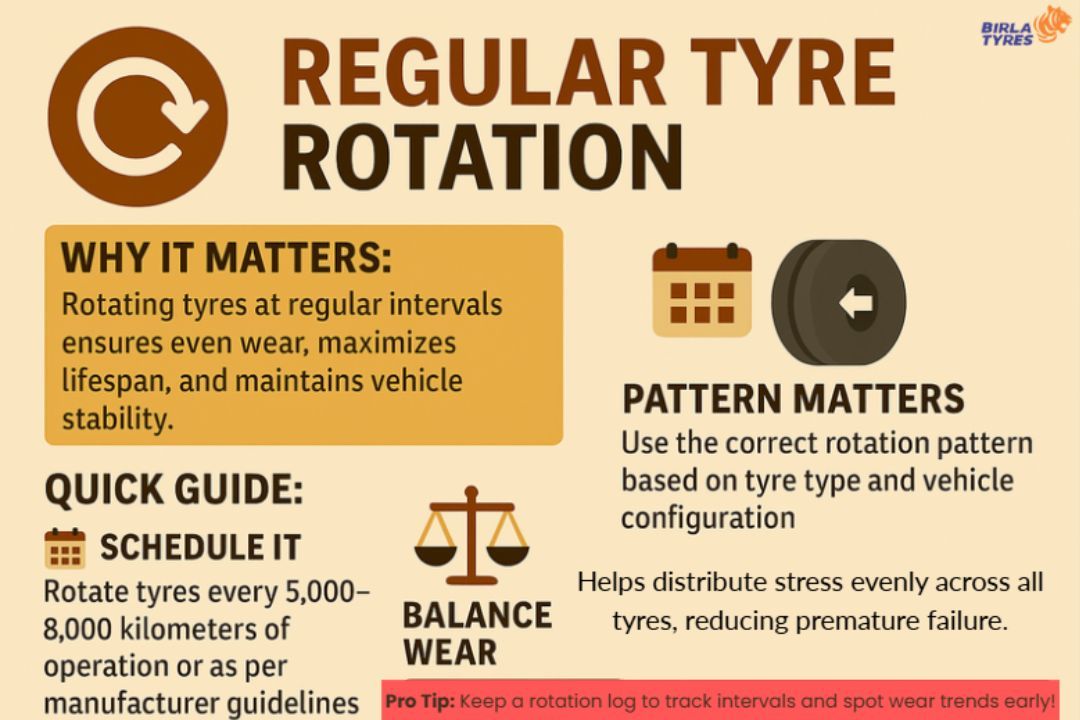

3. Regular Tyre Rotation

The wear of the OTR tyres depends on the intended use and the type of terrain the tyre is used on. Timely rotation of the tyres ensures evenly wearing and improves tyre performance.

Eventually, even wearing of the OTR leads to an extended lifespan and better overall performance.

4. Load Management

With exceeding load ratings, heat build-up becomes an issue. Therefore, load management is a crucial aspect for efficiently maintaining OTR tyres. Check axle weights and adjust tyre pressures to match. Use load and inflation tables or calculators to translate the duty cycle into the right PSI.

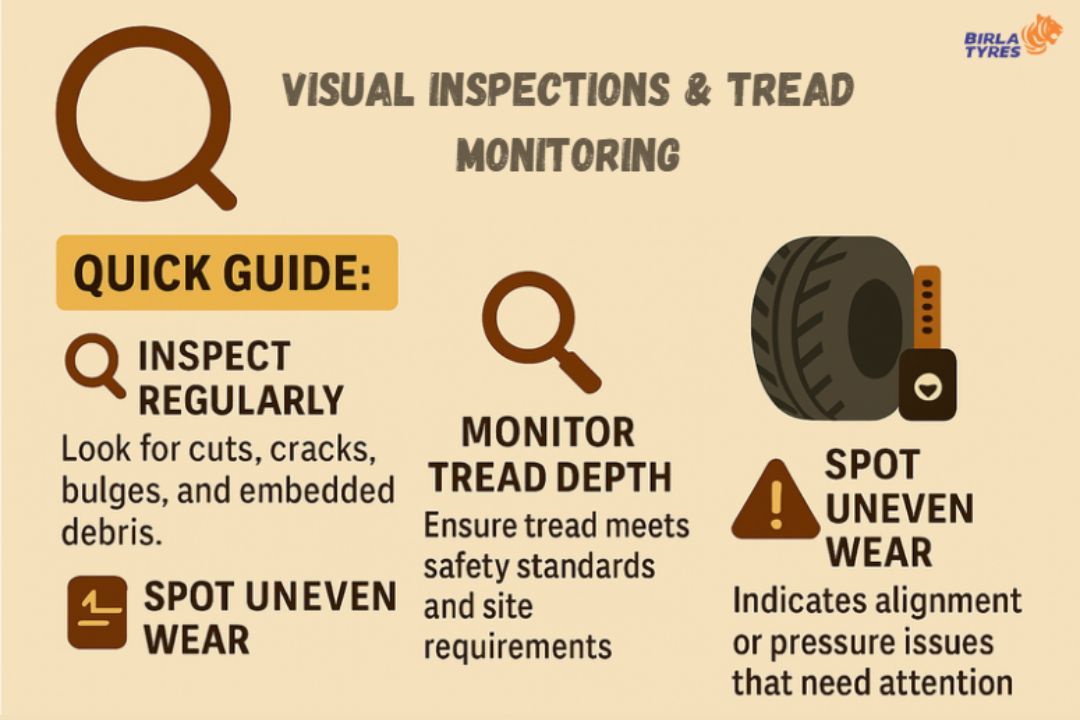

5. Visual Inspections & Tread Monitoring

Tread monitoring and tyre inspection should be part of your routine checks. Look for bulges, cracks, irregular wear, and exposed cords, which are critical red flags.

Go through the formal inspection process to catch issues before they escalate. This should also help preserve casing for retreading and any further escalation of the tyre.

6. Seasonal & Environmental Considerations

Temperature swings in the environment also affect a vehicle’s off-road tyres. Expect a 1–2 psi per 10°F (≈5.5°C) ambient change. It’s best to check the tyre pressure and consider if the tyre will work in those peak situations or not. Additionally, keep the treads clean and the sites drained to avoid hydro-cutting and slips.

7. Heat Management

Higher speeds, longer hauls, and heavy loads on the tyre add heat to the tyre itself. If hot pressure overshoots norms, reduce the cycle severity of the payload and allow cooldown to protect casings.

8. Best Practices for Storage & Handling

Regular checks, visual inspection, and proper use of off-the-road tyres are essential to maintaining their lifecycle. Additionally, consider storage and handling of unused tyres for better efficiency.

Storage: Keep the off-the-road tyres in a cool, ozone, moisture, and oil-free environment. To store the tyre outdoors, use an opaque waterproof tarp to prevent water pooling inside casings.

Handling: Use proper lifting gear/techniques (no hooks into beads), protect sidewalls, and follow installation torque/fitment guidance to avoid bead damage and leaks.

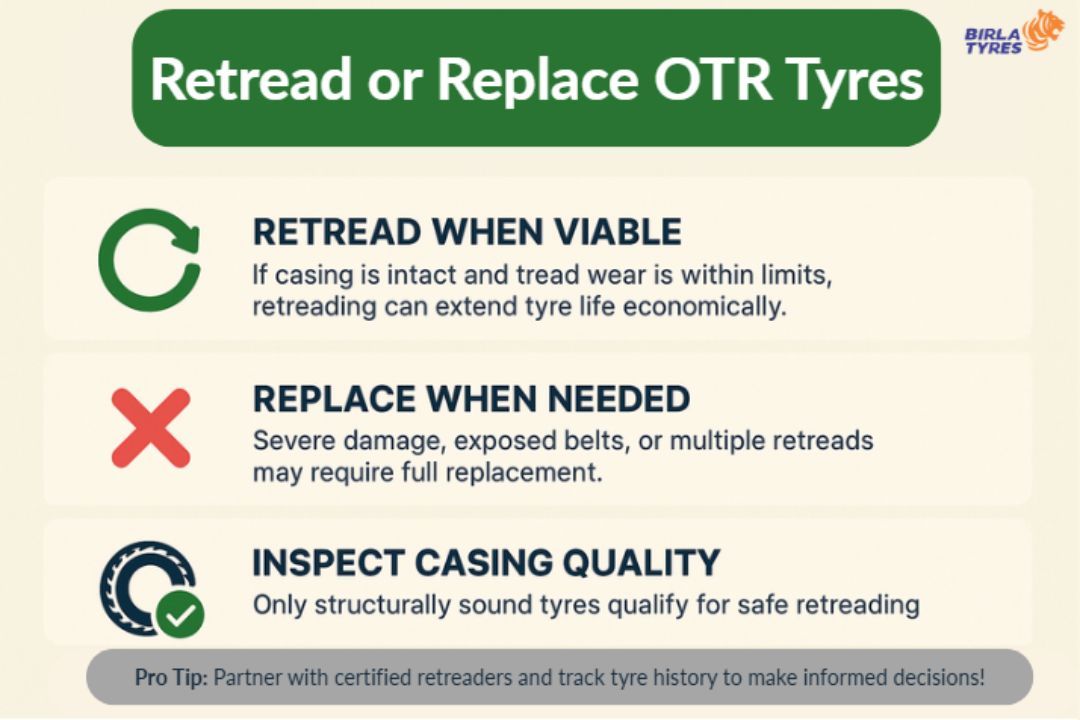

9. Retread or Replace OTR Tyres

When the casing is sound and in a safe condition, retreading can extend the OTR tyre life. However, there should be no ply separation, bead damage, or deep sidewall breaks for the tyre to be retreadable.

Users can reduce the total tyre cycle cost and conserve resources by reusing casings–without compromising safety when done to standard. This is both a cost-efficient and eco-conscious choice for vehicle users.

Maintenance that Pays off

Longevity is engineered, not maintained. Selecting the right bias tyres already helps you choose a solution that stays with your vehicle for a longer period. On top of that, regular maintenance ensures you utilise its full potential throughout the product’s life cycle.

Discover the top causes of uneven tyre wear and how to fix them before it’s too late.

FAQs

How do I choose the right ORT for my operation?

Match the tyre’s capabilities to the specific equipment you have. It helps to look at the job site terrain and operational grounds before choosing any off-the-road tyre. The tyre construction, tread pattern, and size vary depending on equipment and use case. So consider those when buying your off-road tyres.

How Often Should We Check Inflation on OTR Tyres?

Aim for every shift (cold) where feasible; at minimum, daily with accurate gauges/TPMS. Never bleed hot tyres; use cold pressure baselines and treat a large hot‑pressure rise as a heat warning to pause and reassess the duty cycle.

What Rotation Interval Works Best?

There’s no one date‑based rule. Use wear‑rate and RTD to decide, and 8000 to 10000 km is a general practice.