From Bias to Brilliance: Keeping Your Commercial Tyres in Top Condition

Date: 13 November 2025

India moves goods and people on its roads at a historic scale. According to The Indian Express, over 29,000 died in road accidents on National Highways, in the initial half of 2025, which is more than 50% of last year’s count. This count serves as a reminder that every component of a vehicle requires rigorous care, starting with tyres, which remain the only contact with the road surface.

Tyre health and tyre maintenance directly shape safety, uptime, and fuel bills across Indian fleets. The difference between a tyre that drags and overheats and a tyre that has a better grip and runs cool is the difference between avoidable costs and lasting performance.

The Indian Reality in 2025

India’s road risk remains high by global comparison, with official data tracking more than one hundred and fifty thousand fatalities in 2022 and continued growth into 2023. Independent analysis in 2025 underscores that road accidents are a leading cause of death among young men.

This national context places tyre condition at the centre of daily operations for trucks, buses, and light commercial vehicles delivering essentials to every district. Commercial pneumatic tyres in India require IS 15636 certification (BIS), covering dimensional and performance tests (strength, endurance, high speed, tubeless bead unseating, and marking).

Apart from that, Indian road accidents are often caused by overspeeding and poor vehicle condition. The 2023 national report links these causes, highlighting the need for disciplined preventative tyre maintenance.

A Practical Tyre Care Schedule for Indian Fleets

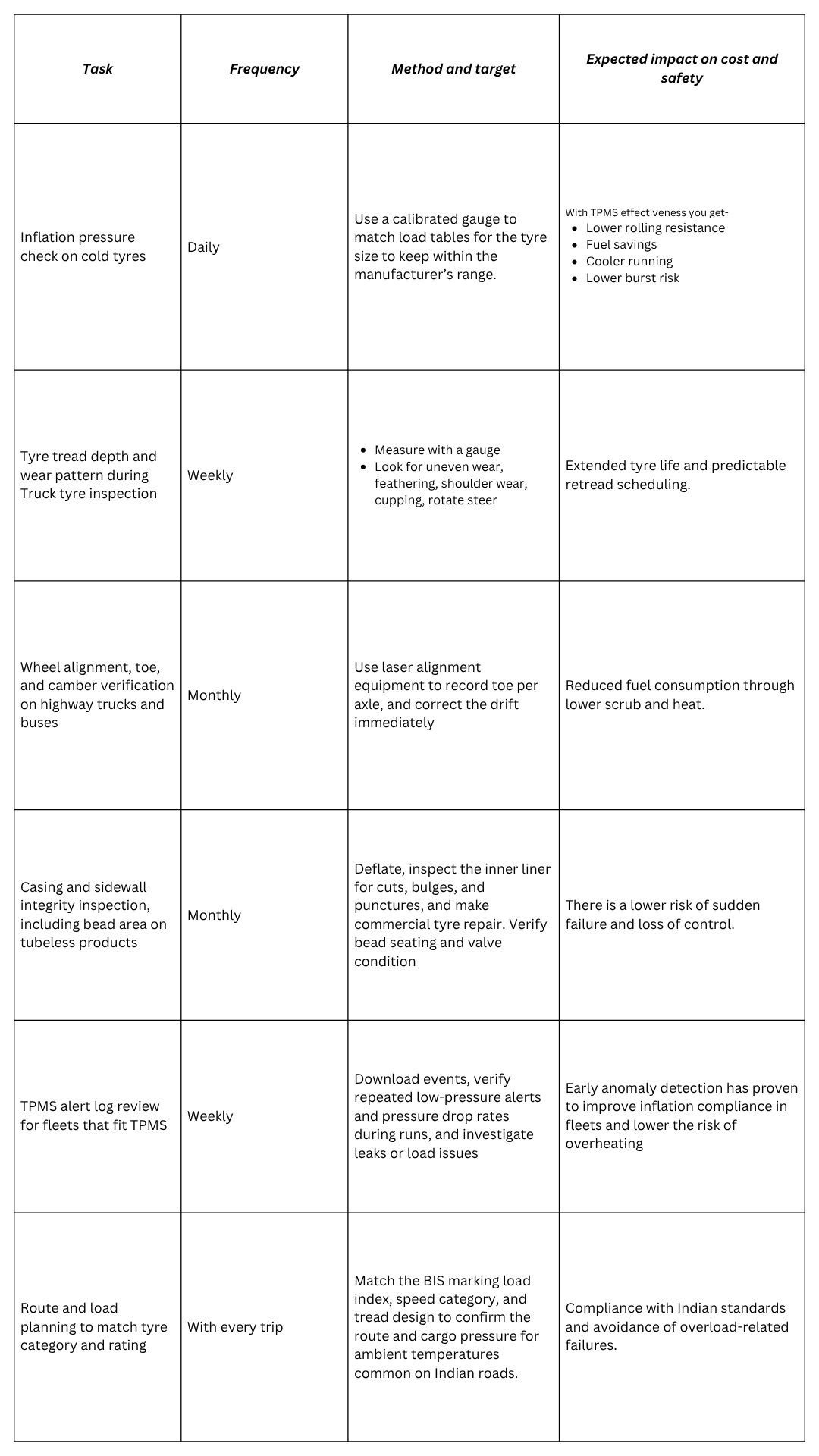

The following schedule blends Indian standards, research insights, and field practice. Adopt it across depots and routes where trucks operate on national and state highways, and on rural roads.

Building Discipline from Depot to Highway

A tyre program succeeds when managers treat pressure, tread, and alignment as production variables, not routine chores. Digital logs and trip-wise checklists drive compliance. Fleet experience and global evidence show that TPMS improves inflation maintenance, which lowers operating temperature and reduces failure risk.

India’s regulatory ecosystem continues to strengthen supervision of highway tyre maintenance and operational readiness, as seen in 2025 circulars that push early planning and inspection rigor across project highways. This wider push for quality amplifies the case for disciplined tyre operations at the fleet level.

Step-by-step Execution: Tyre Maintenance Tips

- Standardise measurement

Calibrate gauges quarterly and retain calibration certificates at depots. Pair readings with ambient temperature notes because pressure shifts with heat across Indian routes. AIS 154’s higher ambient test range reflects precisely this Indian condition.

- Record and audit

Assign responsibility for every tyre, logging fitment, position, rotations, repairs, and pressure checks. Review weekly exceptions and escalate anomalies.

- Align procurement to standards and duty

Source BIS-licensed products and verify ISI marking and IS 15636 compliance. Match load index, speed category, and tread design to routes and axle loads before vehicles leave the yard.

- Integrate TPMS where practical

For long haul or night operations, adopt TPMS. Monitor alerts and pressure history, fix leaks and valves, and retrain drivers who ignore warnings. TPMS monitoring has shown improved pressure compliance and lower burst risk in US fleet studies and manufacturer programs. [fueleconomy.gov]

Avoid the Hidden Causes of Overheating Tyres

Three operational habits destroy tyres and drive fuel bills higher.

- Overload: Extra kilograms elevate carcass deflection and temperature.

- Toe Misalignment: Increased friction and scrubbing against the road surface leads to overheating.

- Underinflation: Low pressure raises flexing and rolling resistance.

What Indian Fleet Managers Should Do?

Tyres translate fleet discipline into safety and savings. India’s standards under BIS and AIS give managers the framework to buy correctly and maintain intelligently. Research and industry programs from 2023 to 2025 provide evidence that tyre maintenance, involving pressure, alignment, and tread monitoring, delivers fuel and uptime gains.

On the agriculture side, Birla Tyres lists clear size and pattern options that fit tractors moving from the field to the highway. Match those listings to duty, run the schedule above, and your fleet moves from bias in practice to brilliance in outcomes.

Frequently Asked Questions (FAQs)

1. Why do commercial tyres go through uneven wear and bias?

Uneven wear mainly results from wrong inflation, overloaded axles, and poor alignment, leading to lower lifespan and performance issues.

2. How often should you inspect commercial tyres for optimal condition?

You should inspect the bus and truck bias tyres once every 10,000 kms or monthly. It will help you avoid costly failures.

3. Can proper maintenance help improve fuel efficiency?

Well-maintained tyres reduce the rolling resistance, enhance fuel efficiency, save money, and reduce carbon emissions.