Protect Your Investment: The Ultimate Guide to Extending the Life of Your Agricultural Tyres

Date: 02 December 2025

Indian farms rely on tyres more than you notice. Every tillage pass, trailer run to the market yard, monsoon season stuck in sticky clay, depends on a few square hands of rubber that transfer power, carry weight, and protect the soil underneath.

In 2025, tyre selection and upkeep sit right next to fuel and service in the list of decisions that decide farm profitability and reduce tyre blowouts. Market trackers place India among the fastest-growing tyre markets, driven by replacement demand and mechanisation. This guide distills proven practices from credible technical sources and then maps them to India-ready products from Birla Tyres, including specific tractor and trailer fitments.

Why do Agricultural Tyres Wear out Early in India?

Tyre engineers describe a three-way link between load, speed, and inflation pressure.

Research summaries across 2024 to 2025 emphasise that lower field pressure with modern casings reduces ground stress, improves traction, trims slip, and protects yields over seasons.

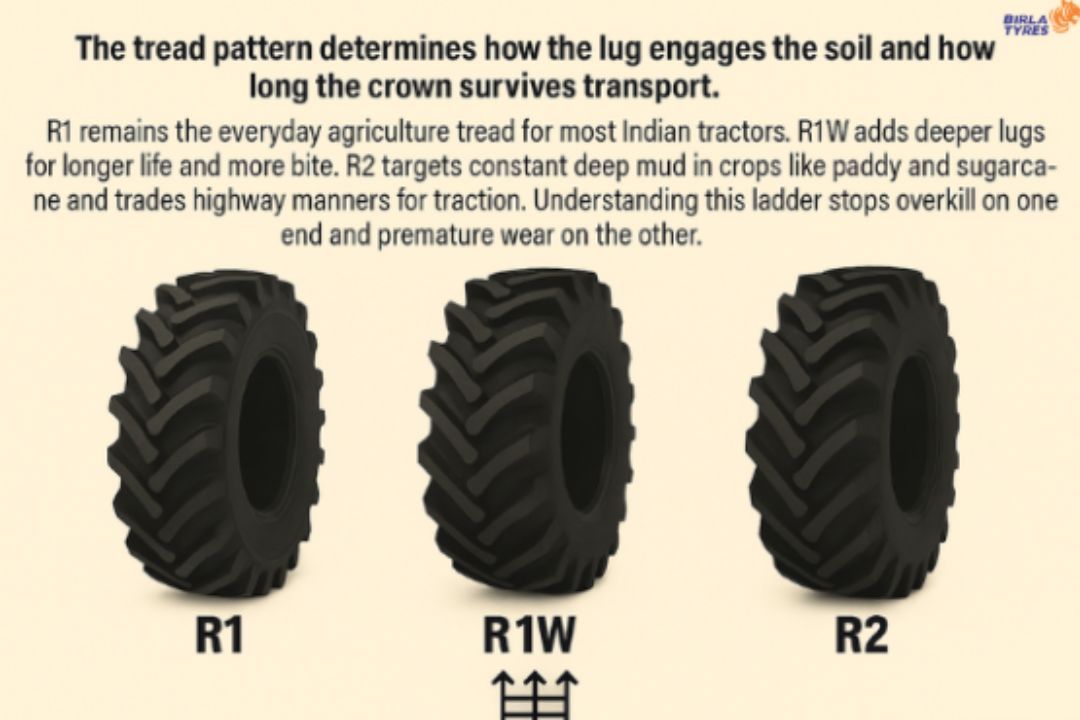

Tread selection that fits Indian soils and tasks

Tread patterns affect soil engagement and longevity. R1 is the standard tractor tread in India. R1W offers deeper lugs for more traction and lifespan. R2, best for deep mud (like paddy), prioritises traction over highway use. Choosing the right pattern prevents both underuse and early wear.

Front rib patterns guide and stabilise steering in row work and on the road. Matching these roles across a tractor-trailer set saves money and downtime across the season.

Pressure Management and The IF and VF Advantage

Set pressure by axle load and speed, not by habit. The correct sequence looks simple: measure load, consult load pressure charts for the tyre type, set cold inflation, and recheck as work changes. Tyre experts treat pressure as the most powerful lever for life and performance because it controls contact area, heat buildup, and wear pattern.

Quick practice: Check tyres cold with a reliable gauge, track loads from implements and trailers instead of guessing, and log separate pressure targets for field and road in the machine file. The benefits include a lower temperature rise, even shoulder wear, and improved fuel use.

Apart from that, Increased Flexion and Very High Flexion tyres carry the same load at lower pressure or more load at the same pressure because the sidewall architecture carries more of the work.

That design lifts traction, limits soil compaction, and extends service life by lowering pressures for field work and restoring them for road work. Field trials and manufacturer data reports show improvements and reduced slip when VF tyres are run at the recommended low field pressures.

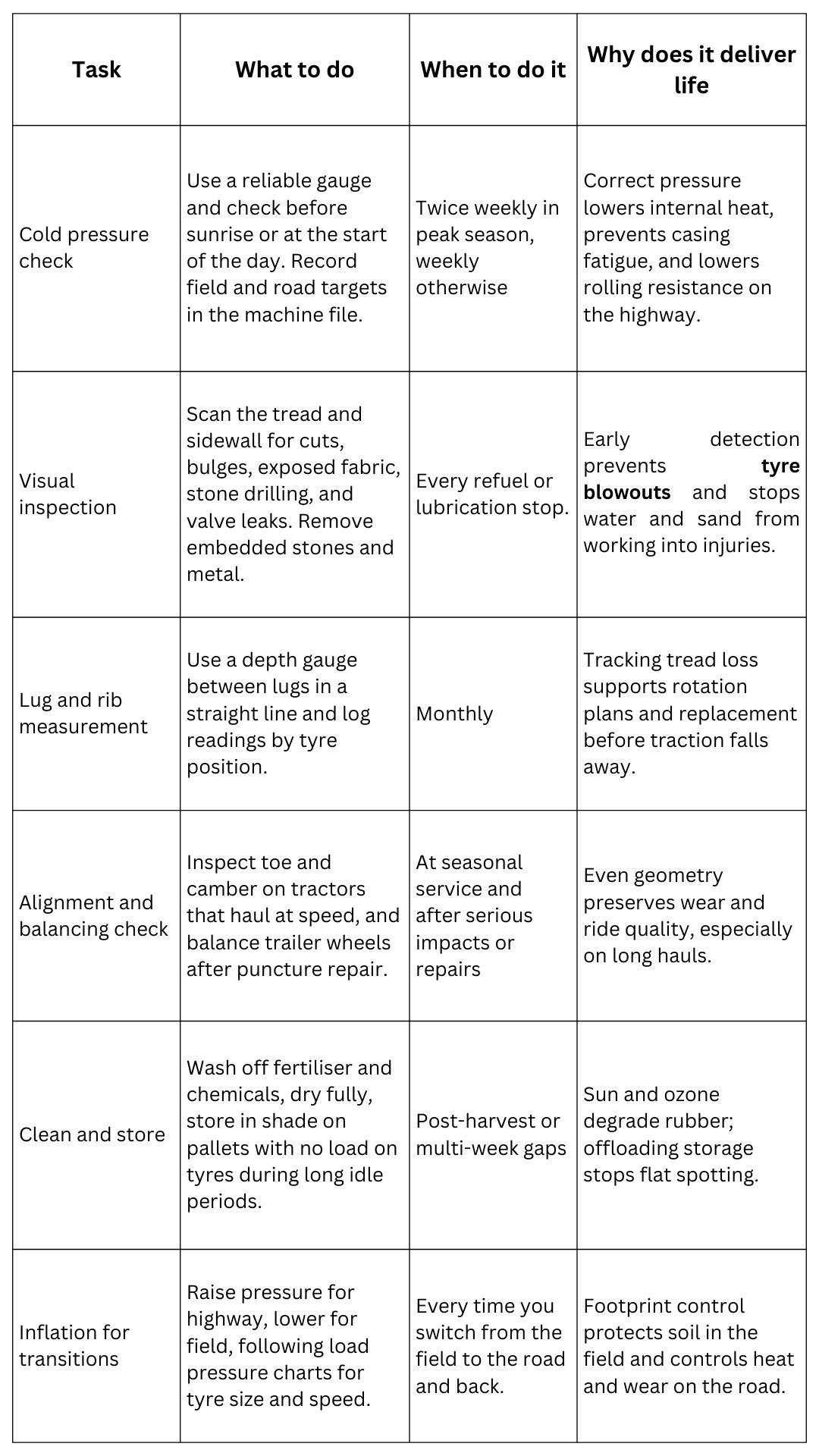

Tyre Maintenance Tips: Do Not Neglect Storage, Inspection, and Rotation

Visual checks for cuts, bulges, exposed fabric, and embedded stones find problems before they escalate. Cold pressure checks are conducted weekly during heavy use to control heat and shoulder scuff. Cleaning the tyre and rim interfaces during service prevents slow leaks.

Wider seasonal gaps invite storage damage from sun and ozone, so shade, cool floors, and off-load storage protect compounds and prevent flat spots. These common-sense steps appear in most agricultural tyres maintenance advisories for 2025.

Map The Right Birla Tyres to The Job

Birla Tyres supplies multiple agriculture patterns that fit mixed Indian duty cycles, with manufacturing and technology rooted in Balasore, Odisha, and a renewed corporate push under Himadri Speciality Chemical Ltd.

Super Plus

Super Plus focuses on traction from an optimised lug layout with a cut-resistant compound and smooth channels that release mud. That feature suits farms where primary tillage and haulage alternate through the season.

Shaan and Shaan Plus

Shaan and Shaan Plus extend the R1 family for rear positions across key tractor sizes, while the Shaan front in rib pattern stabilises steering on front axles. These selections combine common 12.4 to 18.4 inch sizes for the rear and 6.00 to 7.50 inch sizes for the front into one familiar range.

Chakra

The Chakra tyre, with its extra tread depth, cut-resistant compound, and uniform design, offers long life and even wear, benefiting farms hauling heavy produce long distances in tractor-trailer roles.

Birla's focus on digital design, simulation, advanced ply compounds, and a strong technology history directly contributes to product durability and tread life under severe conditions. It adheres to the compliance and quality in the Indian context maintained by the Bureau of Indian Standards.

A Practical Maintenance Calendar that Extends Tyre Life

Final Tips for Indian farms in 2025

Treat air as a working component. Match tread to soil and task. Keep a clean eye on cuts and heat, and repair the right way. When in doubt, pick patterns and compounds from a maker with a plant, a lab, and a line built for Indian fields and roads, to avoid tyre blowouts assuredly.

Frequently Asked Questions (FAQs)

1. Why is tyre maintenance important for agricultural vehicles?

You need to indulge in proper tyre maintenance to enhance the fuel efficiency, reduce the performance downtime, and improve the lifespan of the tyre itself.

2. How often should I check my agricultural tyres?

For agricultural tyres, a weekly check is crucial. Check tyres weekly for real-time pressure, damage signs, and usual wear. Weekly checks help in detecting issues at the earliest.

3. What causes premature tyre wear in farm equipment?

For all farm vehicles, excess weight and constant exposure to flat roads can cause drastic tyre wear. Meanwhile, poor alignment can also be detrimental.