Tackle the Terrain: How to Protect Your Truck Tyres from the Toughest Roads

Date: 02 November 2025

Truck tyres are subjected to unpredictable and harsh road conditions. From gravel, uneven surfaces, to potholes, to shards of glass and nails, a thousand different difficulties exist to affect truck tyres' efficiency.

But if your truck has bias tyres, then it already has some advantages against the harsh roads. However, having bias ply construction doesn't mean cutting down on maintenance and care. We have suggested essential truck maintenance tips to ensure operational discipline.

Additionally, these tyre inspection and maintenance techniques can help your vehicle perform better in challenging situations.

Here's to extending the long life of your bias truck tyre's service life:

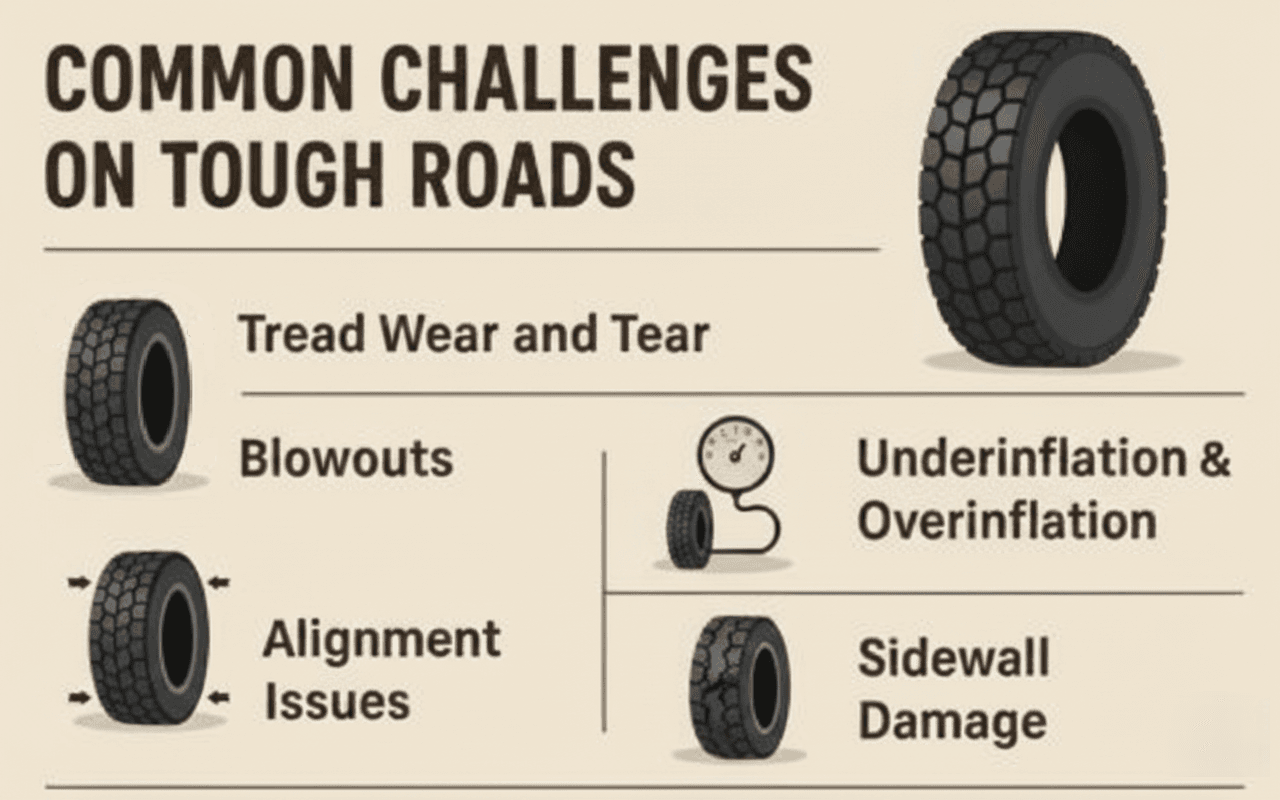

Common Challenges on Tough Roads

Before we get into the truck maintenance tips in detail, let's dive into the issues that impede the performance of bias tyres:

Tread Wear and Tear: Truck bias tyres have tread pattern designs that are responsible for strengthening grip, providing traction, and improving safety on the roads. Over time, tyre tread patterns wear out because of the friction with the road surface. As a result, the tyre loses its efficiency and traction reduces.

Blowouts: Operating on rugged roads with different hazards can cause tyre damage and lead to blowouts. Not maintaining the manufacturer-recommended tyre pressure also leads to blowouts.

Underinflation & Overinflation: Inflation of the tyre plays a critical role in its efficiency. Underinflated tyres lead to shoulder wear, losses structural durability and increases fuel consumption. Similarly, overinflation leads to center wear, increases the risk of blowouts, and reduced traction.

Alignment Issues: Alignment issues with tyres lead to uneven wear. Driving through potholes or hitting curbs causes alignment issues between the wheel rim and the tyre. It's essential to check tyre alignment before it leads to fatal issues.

Sidewall Damage: Commercial truck tyres are prone to sidewall damage. Impacts with curbs, debris, and road hazards cause sidewall damage. Sometimes it can weaken the inner structure and the integrity of the tyre. As a result, the tyre develops the risk of sudden blowouts and failures.

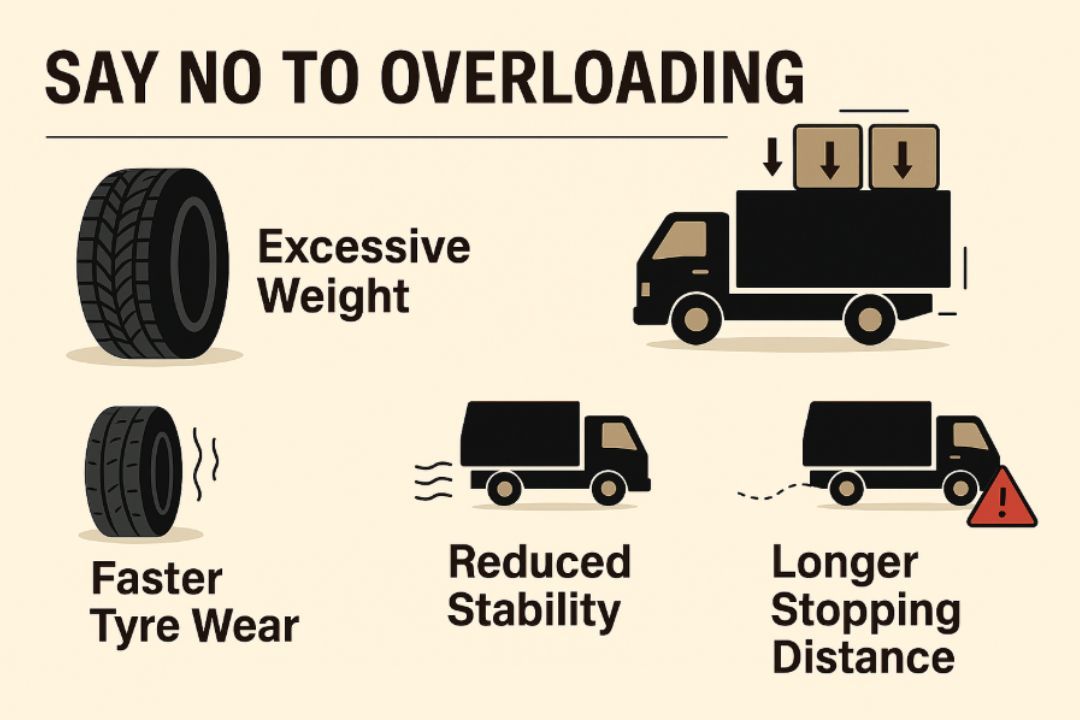

Additionally, negligence of tyre maintenance with poor routine checks leads to faster wearing and damage of the tyre. Overloading also causes sidewall fatigue.

10 Truck Tyre Maintenance Tips: Preventive Maintenance Strategies

Truck tyre maintenance has significant benefits for truck owners and vehicle fleet operators. From improving on-road efficiency to zeroing in on disruptions, the following list of truck maintenance tips will help you safeguard your business:

1. Inspect the Tyre before Heading Out

Before you head out on a journey, check the tyres’ health first. Regular inspection before heading out for a trip or a haulage is crucial to ensuring safety. Additionally, scheduled checks ensure a longer lifespan of truck tyres.

Check all tyres regularly to ensure optimal performance on and off the roads. Regular checks also let you know about the tyre's health and decide if any expert intervention is necessary or not.

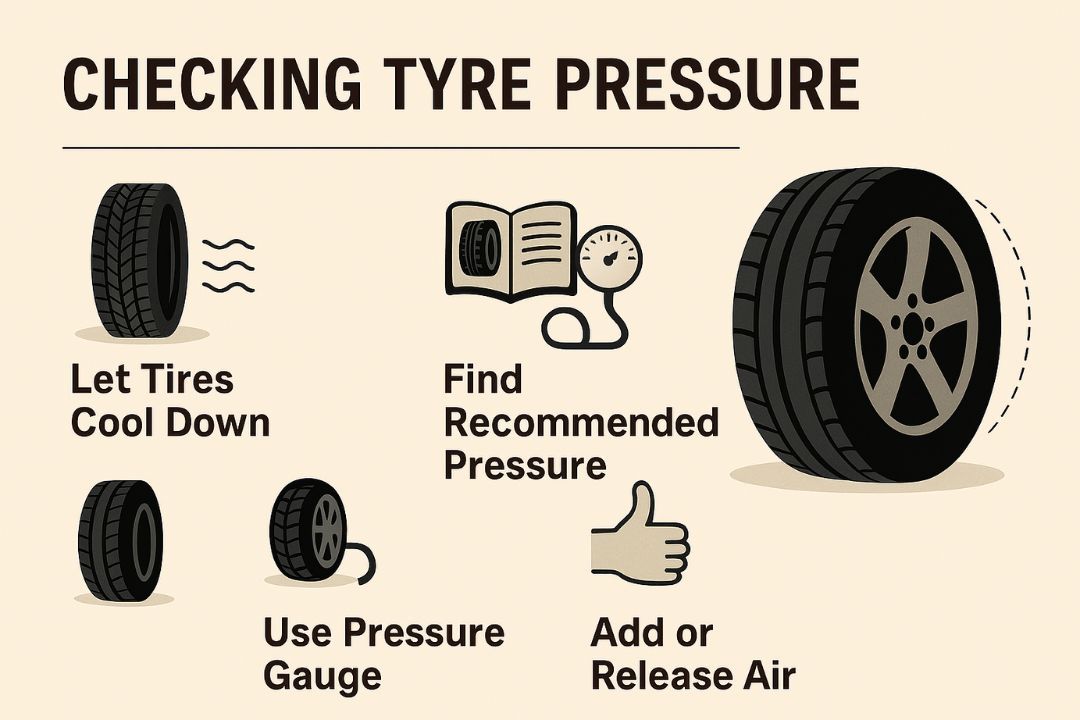

2. Tyre Pressure Checking

Tyre pressure affects a vehicle's efficiency in different road conditions. Vehicle operators and drivers must maintain manufacturer-recommended tyre pressure for safe and optimum efficiency.

Driving a vehicle with properly inflated tyres makes the driving experience a lot safer. Keep the vehicle's tyre pressure within specific parameters described in the user manual, on the tyre's sidewall and as per load.

3. Tyre Alignment Check

If the tyre isn't aligned with the wheel rim properly, it causes uneven tread wear on the tyre. Uneven wearing leads to inefficient output, causes damage to the tyre, and reduces its lifespan. On the contrary, proper wheel alignment ensures a longer lifespan of the vehicle's tyres and improves fuel efficiency and handling on the road.

4. Post Puncture Maintenance

Maintain a routine check to look for damage and punctures on the tyres. Experts recommend using new tubes if you're replacing tube-type tyres. Additionally, stress on post-puncture maintenance since punctures can happen on those tyres again and cause harm to the structural integrity.

5. Allow Proper Cooling Time After Long Runs

After a long journey, tyres heat up due to friction and road temperature. It’s important to let them cool before checking or adjusting air pressure, as hot air expands and gives inaccurate readings. Adjusting pressure while tyres are hot can lead to underinflation once they cool, causing uneven wear and reduced tyre life.

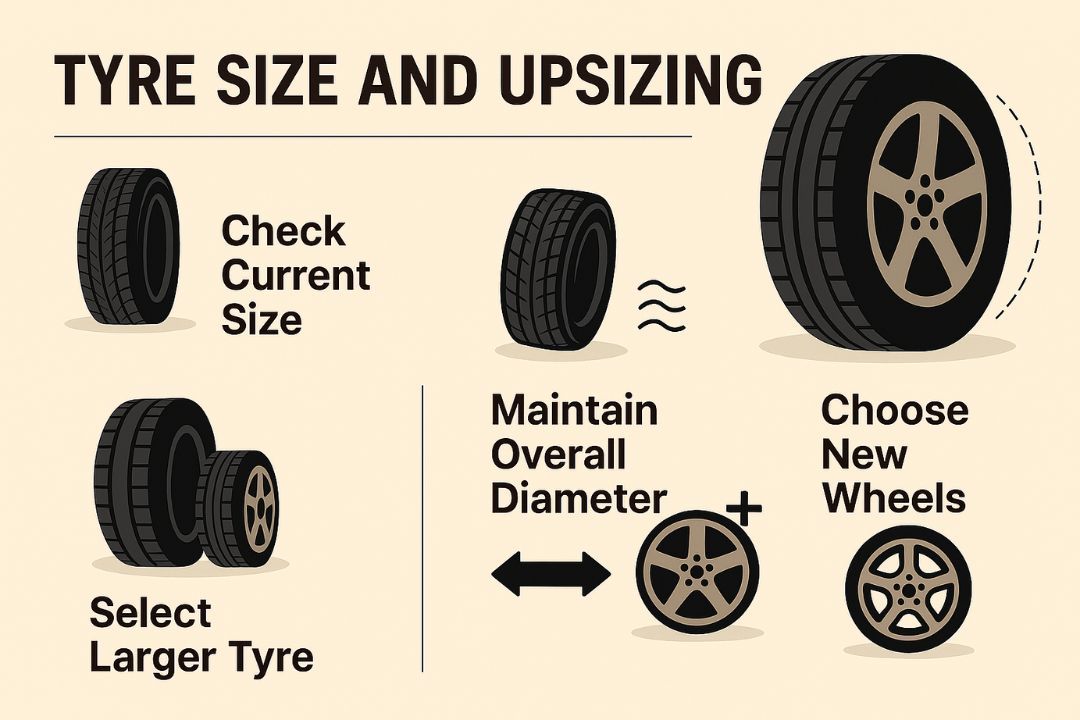

Upsizing or downsizing the tyre, irrespective of the wheel rim size, affects fuel efficiency. Additionally, replacing a tyre with a different-sized tyre without due thought to the manufacturer can also lead to safety risks.

6. Keep Valve Caps Tight & Functional

Valve caps may look minor, but they play a vital role in maintaining tyre health. Always ensure they are properly fitted and not damaged, as they prevent dust, moisture, and air leaks. Missing or loose valve caps can lead to slow pressure loss over time, impacting performance, fuel efficiency, and overall tyre safety.

7. Tyre Rotation

Ensure that your vehicle's tyre wears out evenly and improve vehicle performance by rotating them every 8 to 10000 km or as recommended by vehicle manufacturer. Take your vehicle's hours of operation, terrain, and load cycle into account when deciding on a tyre rotation cycle. This practice not only helps maintain the tyre but also ensures on-road safety, helps the vehicle improve traction, and extends tyre lifespan.

8. Replace Damaged Tyres on Time

Failsafe mechanisms and truck tyre repairs are temporary solutions. If the tyre's damage extends beyond significant damage on the sidewall, replace the tyre at the earliest. Additionally, tyre life depends largely on the driver's driving habits.

Climate, weather, and road conditions also affect the tyre's durability and ability to withstand damage. If the tyre has been damaged beyond its repairable state, replace it immediately. A good sign to look out for would be the tyre tread wear indicators.

9. Maintain Suspension & Brake System Health

Tyre wear often reflects the condition of a truck’s suspension and braking system. Worn-out shock absorbers, unbalanced brakes, or damaged leaf springs create uneven load distribution, leading to irregular tread wear. Regular inspection and maintenance of these systems help ensure smoother rides, improved control, and extended tyre lifespan.

10. Say No to Overloading

The tyre sidewall should mention the load capacity of the tyre and the vehicle. Always carry a load as per the vehicle's load-bearing capacity as mentioned on the tyre sidewall. Exceeding the mentioned load-bearing capacity leads to fast wear of the tyre's tread pattern and often causes potential tyre failure.

Choosing the right bias tyre is just as important as following the different truck maintenance tips. Regular cleaning and maintaining storage precautions are also essential to tyre safety.

Combined Disciplined Driving with Smart Maintenance

There's no alternative to regular maintenance of your truck tyres. Follow the truck maintenance tips we've shared here to ensure safety and efficiency on intended road conditions. Implement a regular inspection process, check for wheel alignment, tread wear, and load maintenance to keep the tyre safe in the long run.

A good practice would be combining disciplined driving with smart maintenance to make a truck fail-safe. Additionally, regular maintenance decreases disruptions in vehicle operations (especially for large supply chains) and improves business efficiency. In short, regular truck tyre maintenance has overarching benefits for a business. Want to know more about commercial bias tyres? Read our other blogs.

FAQs

Why are bias truck tyres preferred for off-road and heavy-load applications?

Bias tyres have a layered diagonal construction, which gives superior strength to the tyre's sidewall. These strengths and durability are critical to absorbing shocks and resisting punctures on rugged and unpaved surfaces.

How often should bias truck tyres be rotated?

It's best to maintain a routine tyre rotation process. Vehicle owners must take hours of operation, terrain, and load cycle into account when deciding their tyre rotation cycle. Usually, experts recommend rotating the tyres within 5000 km to 10000 km of haulage.

What is the primary cause of premature bias tyre failure?

Incorrect inflation is the primary reason for the failure of bias tyres. When the tyre is overinflated or underinflated, it can lead to overheating, flex fatigue, and tread separation.