Tyre Trouble? We've Got You Covered: What to Do When Your Tyre Goes Flat?

Date: 01 November 2025

Whether for public transportation or commercial construction vehicle needs, bias bus and truck tyres have been the cornerstone for India’s fast-paced transportation.

From heavy-duty transportation to hauling passengers, bias tyres equally manage uneven paved roads and sharp nails on construction sites. Additionally, harsh road conditions also reduce a tyre’s lifespan—leading to tyre troubles such as ‘flat tyres.’

Even the most durable bus and truck tyres can fall flat if not maintained well. So, how to fix a flat tyre?

Thankfully, we have the answer. If you are also facing similar issues, don’t panic. First, avoid driving on a flat tyre and turn the hazard lights on. Next, use wheel chocks and reflective triangles before preparing to replace the tyre.

Read on to learn how to implement immediate solutions and build long-term preventive measures.

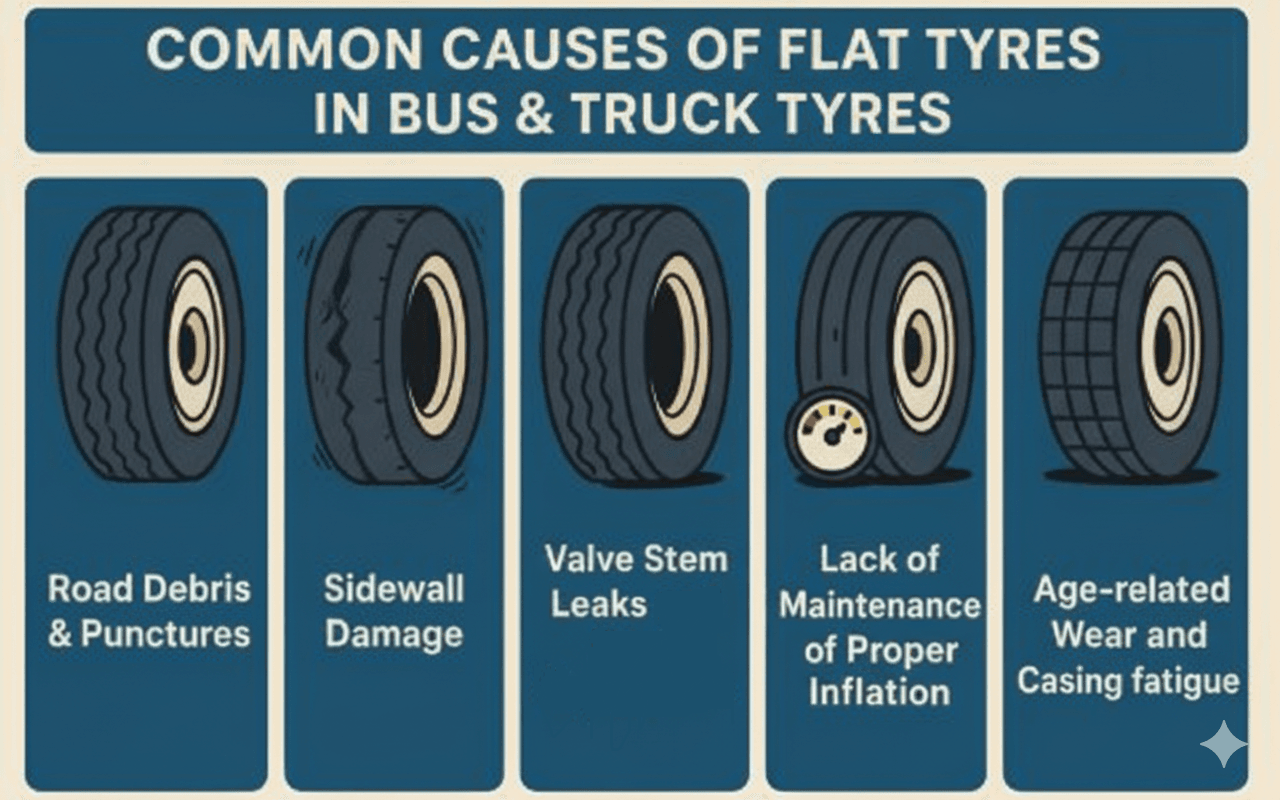

Common Causes of Flat Tyres in Bus & Truck Tyres

Punctures from road debris, sidewall damage, and valve stem leaks are the most common reasons for a flat tyre. The most common reasons that cause tyres to go flat are:

1. Road Debris & Punctures

Bus and truck tyres don’t usually face ideal road conditions. Although bias tyres are formidable against different road hazards, they can withstand damage to a certain extent.

Nails, glass shards, shards of metal, and sharp stones can cause leaks into the protective bias construction and allow the compressed air to escape. As a result, drivers are left to deal with a flat tyre.

2. Sidewall Damage

The main tread area of the tyre is thicker compared to its sidewall. While the thicker tread areas efficiently handle damage, the sidewalls can fall prey to sharp objects and suffer irreparable damage.

Sharp objects on construction tyres can cause deep cuts, cracks, or tyre bulges to construction vehicle tyres. Similarly, bus bias tyres lose the sidewall integrity due to impact from road hazards, improper inflation, and ageing. Both cases lead to tyres losing compressed air.

3. Valve Stem Leaks

Valve stems of a bus and truck tyres can also make way for the compressed air to slowly leak. Wear, corrosion, and improper installation can weaken the valve stem, causing leakage.

4. Not Maintaining Proper Inflation

Overinflation and underinflation are two major reasons for tyre bulges and tyre sidewall damage. When the tyres are overinflated, it’s prone to causing tyre sidewall bulges and blowouts. Overinflated bus tyres are prone to getting cuts and damage when driven at high speeds.

Also, commercial truck bias tyres bulge and flex excessively when operated under the manufacturer-recommended inflation rate. This causes tears in the bias construction and the inner linings. Eventually, the air starts to slowly escape the tyre.

5. Age-related Wear and Casing Fatigue.

Age-related degradation and material fatigue can also cause a tyre to lose air. Constant use and ageing cause permanent flat spots on tyres. With years of use, tyres lose their elasticity and harden, causing difficulty flexing or bulging during impacts.

Additionally, age and fatigue cause internal cracks, making it easy for the compressed air to pass.

Immediate Steps to Take When a Bias Tyre Goes Flat on the Road

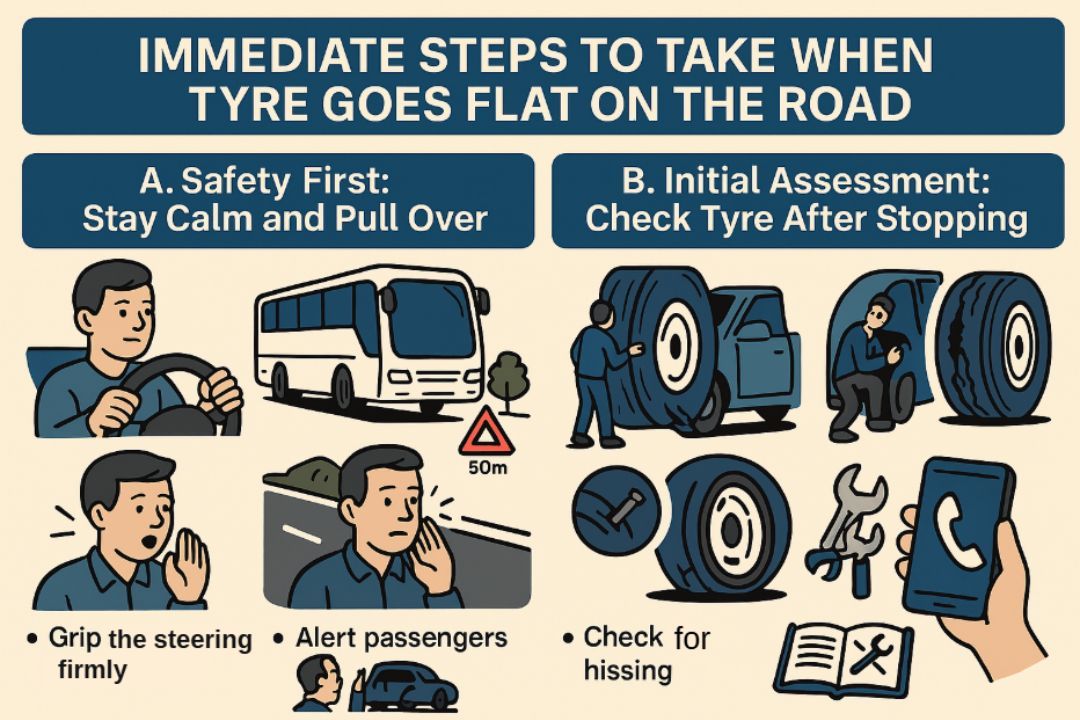

A. Safety First: Stay Calm and Pull Over

Grip the steering wheel firmly when the tyre has instantly punctured and become flat. Air loss causes the flat tyre to pull the vehicle to one side.

With a strong grip, you can counteract this pull and steer the vehicle in the right direction. Once you have control, stop the vehicle at a safe location ( wide shoulder or emergency bay). For bus drivers, it’s best to alert the passenger about the condition.

B. Initial Assessment: Check the Tyre after Stopping

Alert other drivers on the road after you have pulled over and reached a safe location on the road. Turn the reflective triangles or flares on to signal others within 50m to 150m of radius.

Next, safely step outside the vehicle and start your initial assessment. This is where you analyse why the tyre became flat suddenly:

- Identify the point where the tyre is damaged. Check for hissing sounds or spot the area of the tyre that’s punctured.

- Check the extent of the tyre’s damage. Is the tyre completely shredded, or is there a crack between the wheel rim and the tyre?

- You must change the tyre yourself. It’s best to have prior experience of changing a tyre. If you’re changing the tyre yourself, check the owner’s handbook before you do so.

- If you lack the expertise and the tools needed for replacing tyres after they flatten, call for help. Start by asking for roadside assistance.

How to Fix a Flat Tyre: Emergency Repair Options

Once you have spotted the damaged area or the area of the tyre’s puncture, assess whether it’s possible to repair it or not. Minor damage to the flat tread surface of the tyre is easy to repair. However, large cuts and shreds along the sidewalls are not repairable.

For minor and repairable damages, try the following tips:

A. Temporary Solutions

For emergency repair of a bias ply tyre, the primary options include:

Using Tyre Plugs: This is a quick and roadside method to make the vehicle operational. Use sticky, cord-like strips of rubber. These materials instantly seal smaller spots of puncture and close the spot using the cement that comes with the plugs. Remember, this is not a complete solution.

You’ll have to get the tyre checked once you arrive at the garage. The plugs are temporary solutions and only the crown area of the tyre works with plugs.

Remember, patches or plugs are ultimate solutions after your tyre has gone through damage. These are primary and preventive measures to use till you reach a garage or get the tyre changed.

B. When to Ask for Roadside Assistance?

Quick fixes don’t apply to larger tyre damage. Once the bus or truck tyre goes flat due to large cracks or extensive sidewall damage, it’s best to call for roadside assistance.

Additionally, if the tyre has suffered multiple punctures or bead separations, call for roadside assistance. Instantly replace the damaged tyres if you have the tools and expertise to do so. You should also call out for help if you don’t have access to the necessary tools or a spare bias tyre.

Preventive Measures to Avoid Flat Bias Tyres

Although it’s impossible to avoid sudden failures, drivers can reduce the chances of tyres flattening and blowouts through regular maintenance. Take the following precautions to avoid tyre troubles:

Regular Inspection: Look for different signs of tyre damage such as cuts, cracks, and bulges on the tyre. Fix repairable damages before heading out for a haulage or a journey. Precautions maintained daily can help avoid on-road distress.

Maintain Correct Inflation Pressure: Always maintain manufacturer-recommended tyre pressure for both daily and off-road usage.

Avoid Overloading: Avoid overloading, whether it’s a commercial vehicle or public transport. Excessive weight on the tyre can cause it to lose its efficiency and easily crack.

Practice Good Driving Habits: Avoid harsh and rapid braking. Accelerating fast and taking sharp turns causes wear and tear in the tyre—especially when the vehicle is carrying heavy loads. Avoid potholes and other road hazards when driving.

Use Tyre Pressure Monitoring Systems: Commercial fleet owners can rely on tools like TPMS to inspect the health of the tyres and take action as necessary.

Look Beyond Emergency Situations!

As a vehicle owner, your answer of how to fix a flat tyre depends mostly on your dutifulness to the vehicle’s safety. A significant part of this involves checking the tyre’s health on a timely basis and repairing and replacing the tyre if necessary.

If you’re a fleet owner, build mandatory training plans to train technicians and drivers on ways to deal with tyre troubles like this one. But if you’re already facing the crisis, this guide on how to fix flat tyres must help.

Eventually, look beyond solutions for emergency situations. Follow safe tyre maintenance protocols and practices to avoid certain perils on the roadside.

FAQ

How do You Fix a Flat Tyre?

Fixing a flat tyre depends on the degree of damage and puncture. If the cut and puncture is smaller in size, a patch or a plug is enough to deal with the situation. Replace the tyre if the sidewall is damaged or has larger cuts. Consult an expert if you are doubtful about your decision. For severe cases, always reach out for roadside assistance.

Can I Drive with a Nail in My Tyre?

Don’t drive on a tyre with a nail in it. Doing so will cause further damage to the tyre. It’s best to remove the nail and use a failsafe tyre plug or patch till you reach a garage. Multiple punctures on a tyre need an expert’s attention. Maintain post-puncture guides for a safer driving experience.

Can I Drive on a Slow Puncture?

It’s not recommended to drive on a slow puncture. It causes irreversible damage. Get the tyre inspected by an expert as soon as possible and seal the puncture at the earliest.