Choosing the Right Bias Tyre as per Your Vehicle & Application

Date: 25 September 2025

The performance of heavy commercial vehicles depends on the conditions they are exposed to and the terrain they run on. When it’s about reliability in the fields, construction sites, transport highways, or behind a trailer, bias tyres remain a trusted solution for millions of vehicles.

The most interesting part about bias tyres is their construction. These tyres have a crisscross design, with the fabric cords running across the tyre diagonally. The robust design of these tyres makes them efficient on the highway, off-road, muddy, and often on snowy terrains.

However, vehicle owners often make mistakes in choosing the right bias tyre for their vehicle. Sometimes, errors occur when selecting the wrong tyre pattern, ignoring the specific needs of certain application, or overlooking the ply construction process tailored to a particular driving environment.

Lack of knowledge about the bias tyre variations causes increased tyre cost. It means you fail to choose vehicle-specific tyres and end up spending an unnecessary amount on tyres your vehicle doesn’t need.

Considering the rising safety concerns and need for regulatory compliance, it is a heavy price you’re paying in the long term. But that’s going to change once you go through this article. We’ve discussed the right way to choose a bias tyre for your vehicle in this blog post. Let’s get to it.

The Foundation: Understanding Bias Tyre Construction

Bias tyres possess immense durability, owing to their innovative internal structure. Different layers of plies of tough fabric cords arranged at alternate angles, usually between 30–40 degrees from one bead to the other, contribute to the durability of bias ply construction.

The solid crisscross design of the bias ply construction helps vehicles withstand tough terrains and handle heavy loads. In fact, Bias tyres are inherently capable of absorbing significant shock and resisting punctures and damage from difficult road environments.

These Agricultural tyres are most favored for agriculture, construction, short haulage, and construction work. However, biased tyres meant for different vehicle usages have significant variations in ply constructions.

Key Variations Among Bias Tyres

Here’s a truth: bias tyres have similar ply construction, but not all of them have the same ply rating. Sidewall thickness, tread compound, and patterns of bias tyre design also cause variations in bias tyre sidewall design. The following are the most common parameters for understanding tyre ply variations:

Ply Rating: It represents the tyre’s strength and load-carrying capacity, rather than the actual number of layers. A higher ply rating means that a bias tyre has a higher load-bearing capacity. It has a stronger resistance to off-road equipment.

Vehicles with light-duty applications for bias tyres can use 12-14 plies. For heavy trucks, off-road vehicle equipment, or trailers, this can rise to 16-18 ply rating for tough environments.

Tread Design: Tyres that are designed for agricultural vehicles have deeper lugs for traction. On the other hand, trailers and truck versions can use flatter patterns for improved rolling stability. The rubber compound can also be tuned for abrasion resistance and flexibility as needed.

Sidewall Strength: The sidewall and the tread patterns reinforce each other in bias tyre designs. Both play critical roles in giving the tyre the capacity to endure impacts and maintain endurance and shape under stress. It’s vital to consider these aspects when choosing a bias tyre for your vehicle.

How to Choose the Right Bias Tyre for Your Vehicle?

Choosing the right bias tyre requires an understanding of the terrain and the application of the tyre on your vehicle. However, it’s also crucial to understand the variations of ply rating, tread design, and sidewall strengths.

We have suggested some tips for choosing the right bias tyre for different vehicles below:

1. For Tractors

Tractors are used for both Agri & haulage application. Therefore, it’s critical to consider both terrains and the application of the tyre when choosing the right bias tyre.

Ply Selection: Ply selection for bias tyres must align with the vehicle's weight and the field load. Tractor bias tyres typically have 8 to 14 ply rating, depending on the terrain and application. Ensure that the bias tyres are compatible with the tractor rims to avoid stability issues.

Traction and Protection: Choose a bias tyre with deep and aggressive treads if your tractor has to constantly do field work in wet, muddy, and soft soil. But, if it’s required for more road transportation, then tyres with shallower treads and lower rolling resistance are ideal. Deep, well-spaced lugs improve traction and self-cleaning in muddy or loose soil.

Durability Focus: Durable rubber compounds on the tyre tread design ensure resistance to wear on a hard surface. However, Bias tyres manufactured by Birla Tyres are designed with reinforced sidewalls that offer strong resistance to damage in rugged environments.

2. For Heavy-Duty Truck Tyres

Trucks that regularly haul hefty loads need tyres as tough as their cargo. Here’s how to choose a truck tyre

Ply Rating: Birla Tyre’s heavy-duty truck applications have varying ply ratings. Trucks with 10.00-20 size usually have a 16 ply rating for the maximum loaded weight of the vehicle.

Birla Tyres’ heavy-duty tyre range (Birla Tyres Kalapatthar range) for mining trucks and other heavy equipment has specific ratings for specific applications. Tyres like XPL LG, or Ultra Miler Platina can withstand in heavy load application. Heavy-duty trucks shouldn’t have low ply rating to avoid risks of premature failure.

Sidewall Robustness: Stiffer sidewalls help in reducing sway and protect against curb and pothole damage.

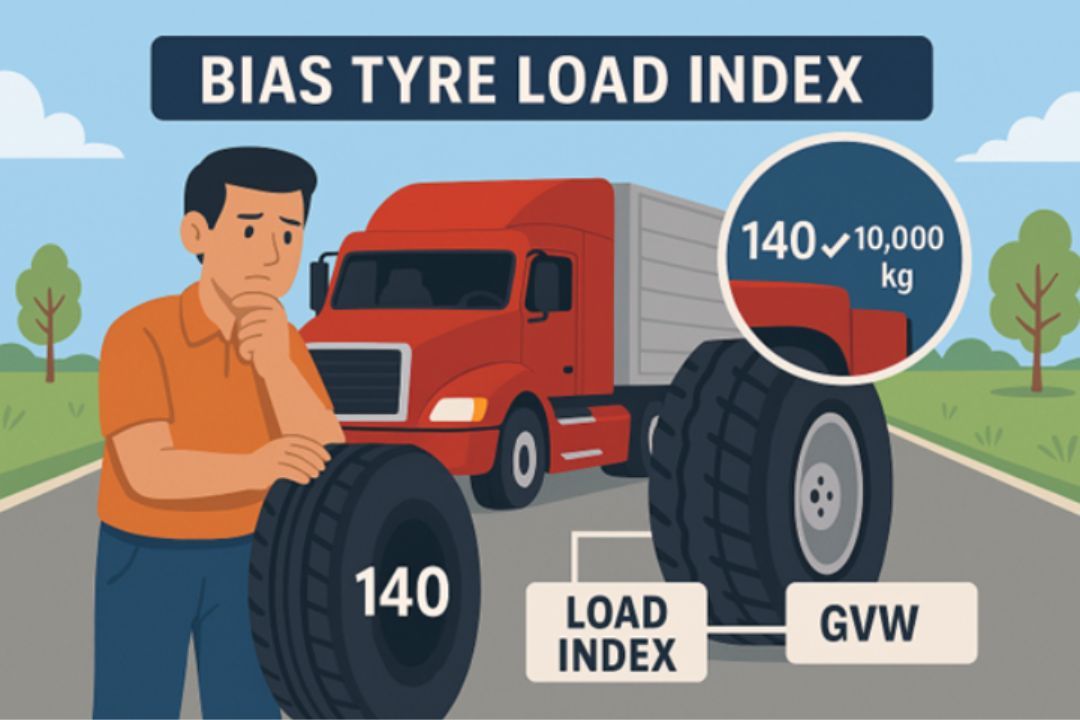

Load Index: Consider an alignment between the tyre’s load index and the gross vehicle weight (GVW) of the truck while choosing a bias tyre. Consider if the tyre’s load index is adequate according to the GVW. A misalignment between them would cause premature failure.

3. For Off-Road & Construction Vehicles

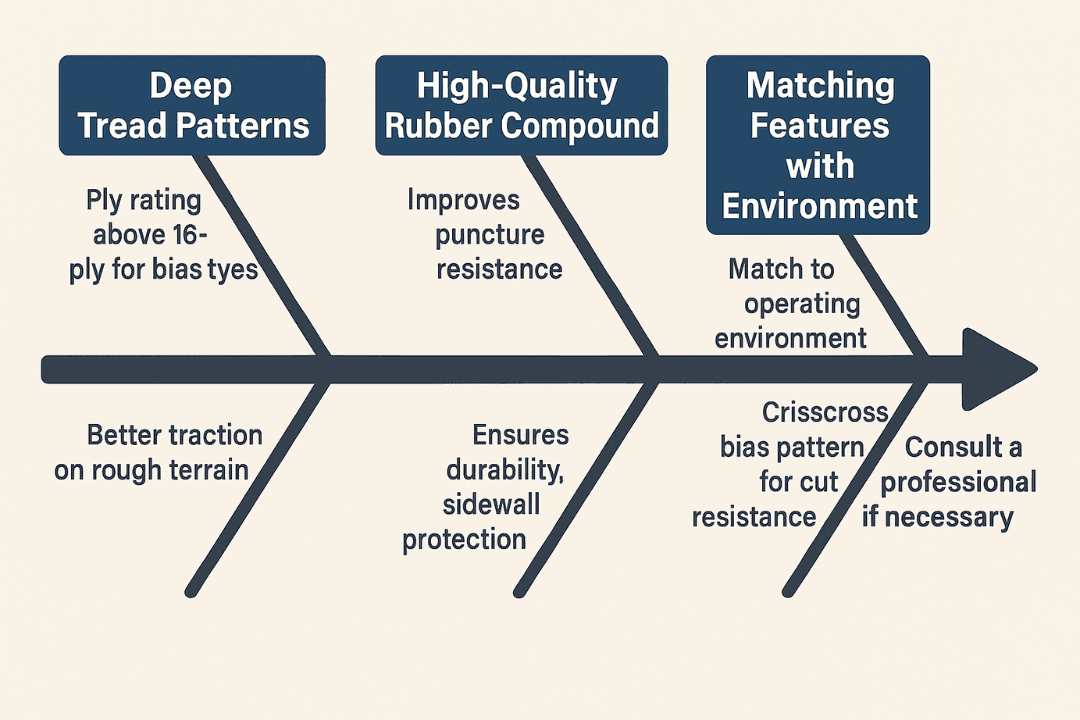

Deep Tread Patterns: Again, for off-road tyres, the ply rating for bias tyres must be above 16 ply rating with variations considered according to terrain and applications. It’s best to go for deep tread patterns for better traction on the rough terrain.

High Quality Rubber Compound: high-quality compounds improve resistance against puncture and ensure durability, reinforcing the sidewall to protect against cuts and impacts.

Matching Features with Environment: Match the feature of a construction-vehicle bias tyre with a specific operating environment and vehicle tyres. Loaders, site vehicles, and earth movers constantly face hazards like rocks, spikes, and sharp nails.

Consider bias tyres that are efficient in such an environment. Additionally, a crisscross bias pattern design dramatically improves the tyre’s resistance to cuts and punctures. Consult a professional if necessary before you choose a bias tyre for your construction vehicle.

4. For Trailer Tyres

The right trailer tyre design depends more on the load frequency and application of the trailer’s operation.

- 7.50-16 (Tractor Trailer): 16 PLY Rating

- 9.00-20 (Truck Trailer): 16/18 PLY Rating

Proper ply rating selection for trailer bias tyres reduces the chances of blowouts. Additionally, a matching application for the vehicle’s purpose is critical for a smooth experience. Heavy load trailers need robust, impact-resistant tyres, while highway trailers might focus on even treadwear and a smoother ride.

Why Birla Tyres Is a One-Stop Solution for Your Bias Tyre Needs?

Birla Tyres stands at the forefront of tyre technology and is a leading manufacturer of commercial bias tyres. We are committed to meeting the evolving environment of India’s tyre requirements, staying compliant with upgraded technologies, regulations, and quality control.

If you’re planning to purchase a truck tyres or construction tyre, we have a wide selection of products with different vehicle and environment needs. We assure quality, efficiency, and safety with advanced ply construction tailored for trucks, tractors, trailers, and off-road vehicles.

Our customers benefit from the innovations at our R&D, the after-sales services, and, most importantly, a deep understanding of the regional terrain—from fertile fields to urban highways and rugged job sites.

FAQs

What are the Advantages of Bias Tyres?

A: Bias Tyres has a strong, flexible sidewall design. Birla Tyres provides a superior grip on uneven terrain and a smooth ride, even on rough and rugged surfaces.

Can You Mix Radial and Bias Tyres?

A: It’s not recommended to mix radial and bias tyres for optimal performance and safety. We don’t recommend mixing radial and bias ply tyres on your vehicle. These two tyres are designed for different applications, and combining them on your vehicle can negatively affect your ride quality and increase tyre wear.

Do Bias Ply Tyres Have Steel Belts?

A: No, bias tyres are built with cords of nylon or polyester laid diagonally at a 30–45° angle to the tread centerline, crisscrossing from bead to bead. In contrast, radial tyres have steel cords arranged at 90° to the tread centerline.