Agricultural Bias Tyres: When You Can Repair—and When to Replace

Date: 16 September 2025

In modern farming, reliance on agricultural equipment has transformed the production process, improving the agrarian process from sowing to harvesting. Tractors have a critical role to play in agriculture.

Therefore, the critical tool to a major part of India’s economic backbone (agriculture) demands significant attention, and that includes agricultural tyres—especially the bias-ply tyres.

Bias-ply tyres are widely preferred in India for the rugged nature of the Indian fields. At Birla Tyres, we aim to set a benchmark in the segment, providing reliable, durable, and capable tyres at farmer-friendly pricing and robust after-sales support.

However, similar to all mechanical components, tyres are also prone to wear and damage. It leaves farmers with a very important question:

When is the right time to repair an agricultural tyre? And when is the right time to replace it? The good news is, we have the answer. Continue reading to find out.

Understanding Agricultural Tyres

Agricultural bias tyres are engineered with versatile field performance as a priority. These tyres are capable of handling higher stresses. The multi-layered nature of the tyres, with their crisscross constructions, provides:

- Excellent grip and traction on loose, wet, and uneven fields. It enables the tractor to stay stable on the uneven and rugged terrains of the field.

- A strong load-bearing capacity—essential for transport jobs and heavy implements.

- Superior puncture resistance and durability for the farming conditions in India.

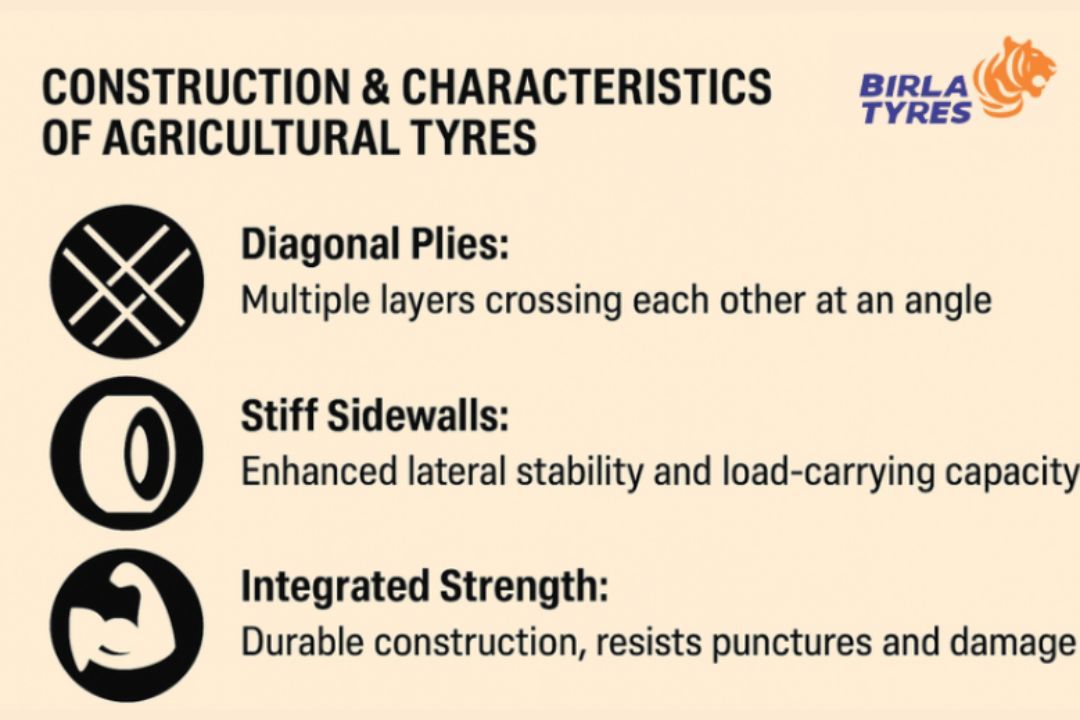

Construction & Characteristics of Agricultural Tyres

Diagonal Plies: Multiple layers of fabric plies are laid diagonally from bead to bead. Each layer of fabric plies is set at an opposing angle to create a crisscross pattern.

Stiff Sidewalls: The crisscross design of the agricultural bias tyres leads to a thick tyre construction with a strong sidewall design. Such construction features make the bias tyres resistant to punctures and damage from rough terrains.

Integrated Strength: The side wall and the tread have the same reinforcing plies, providing strength and endurance to the overall structure of the tyre.

At Birla Tyres, we have a range of agricultural tyres with models such as Farm Haul Platina, Super+, Shaan+, and Chakra.

The tyres are designed around self-cleaning tread pattern designs. Additionally, the tyres are resistant to cuts and bruises and are capable of performing with significant loads.

The tyres come in both mini and commercial tractor sizes, ensuring every farmer finds the right fit for their manufacturing demands.

When to Repair Agricultural Tyres?

Some specific types of damage and wear to the tyre are repairable. However, it’s best to replace the tyre on your tractor as soon as any “significant” damage occurs and avoid hazards.

Common Types of Tyre Damage

Agriculture bias tyres for tractors are generally strong and durable. However, different field hazards introduce risk to the tyre and cause various types of risks. The following are some common damages caused to bias tyres by field hazards:

- Puncture from thorns, nails, and sharp field debris causes damage to the bias tyre.

- Surface cracks on the tyre due to exposure to UV, age, and persistent underinflation also cause damage to the tyre.

- Minimal tread wear or shallow cuts from stubble and rocks are also possible.

- Small injuries to the tyre sidewall from hidden obstacles and implements.

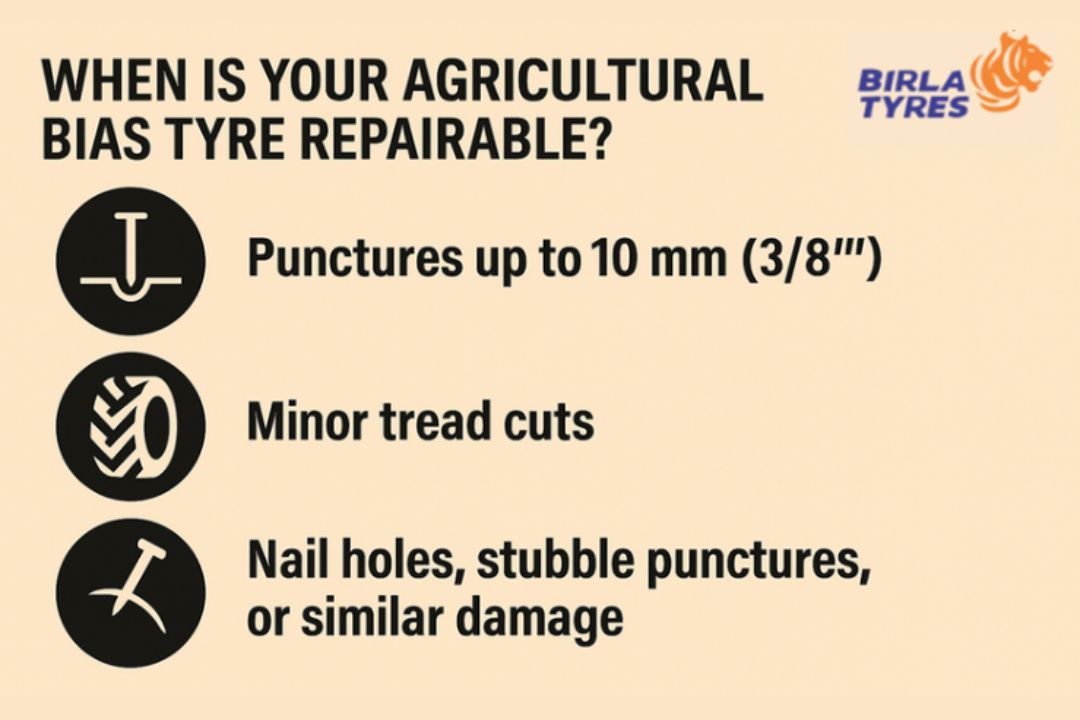

When is Your Agricultural Bias Tyre Repairable?

It’s critical to follow the industry standard guidelines for Bias tyre maintenance. If you’re using Birla Tyres, the following are the scenarios under which we recommend a repair:

Punctures up to 10mm (3/8”): Clean and central tread punctures are generally safe to plug and patch. However, injuries larger in size require professional section repairs.

Minor tread cuts: Tread cuts that don’t penetrate all layers or reach the casing of the tyre are also repairable.

Nail holes, stubble punctures, or similar damage: these damages cause air loss in the tyre and weakens the structure and potentially lead to blowouts and complete failures. Regular inspections can help keep track of damages that are still repairable.

Tyres with the above conditions are within the safe boundary where you can repair and reuse them.

Step-by-Step Repair Procedures for Agricultural Bias Tyres

Follow this step-by-step process to clean and repair the tyre:

Thorough Inspection

Start with a thorough inspection of agricultural tyres before repairing them. Remove and isolate the tyre from the vehicle for close inspection under strong light.

If the tyre has endured extensive damage and cracking, exposed cords, or bead/wire separation, then you must reject it. Make sure to use protective gear and ensure that the tyre is completely clean.

Preparing for the Injury

Mark and remove any foreign material attached to the tyre before repairing it. Scrape and scrub the area with significant damage and stretch at least 25 mm beyond the injury on all sides. Keep the surface dry and buffed to clean contamination without damaging the cord structure.

Applying the Repair

Use only bias-ply repair patches on bias tyres. Make sure that the patch overlaps the injury at least by 25%. Additionally, use a cement that’s compatible with the plugs/patches. The following are the material markers’ instructions.

Use repair cement and elements that are best suited for the tyre. When using self-vulcanizing putty, allow enough curing time before you remount it.

Test for Pressure and Load

Inflate the tyre to the manufacturer's recommended pressure points. Also, test with the recommended load on the vehicle before reverting back to regular use. However, remember to drive within the prescribed speed limit to avoid faster degradation or compromising the repair.

Agricultural Tyre Safety and Compliance

Refrain from repairing tyres that are overly damaged or have significant damage to the sidewall and the bead area. Always replace the tyre if more than three repairs overlap. Also, if multiple repairs come within a circumference of 100 mm, it’s time to remove the repair.

Additionally, document your repairs in the farm maintenance log for compliance and warranty claims. Keep the repairs compliant with the recommendations from the manufacturers. Use recommended kits for repair and follow the guidelines thoroughly. If you’re using Birla Tyres, follow guidelines from Birla and central safety bodies (BIS/ISO).

When to Replace Agricultural Tyres?

Replacement is the best solution for Bias Tyres if it has suffered damage and tears over a period of time.

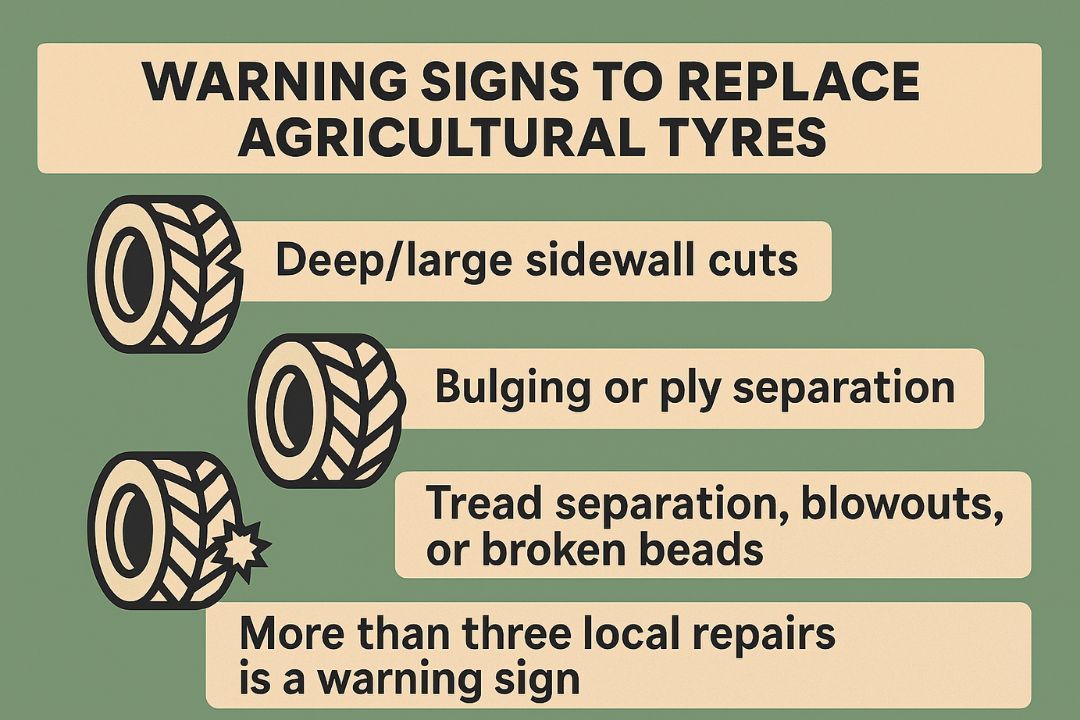

1. Warning Signs for Agriculture Bias Tyre Replacement

The following are the warning signs that indicate a replacement is necessary:

Deep/large sidewall cuts: when a gash is extended to the casing or through it, the tyre becomes unsafe, hence requires a replacement.

Bulging or ply separation: Tyres with bulges, blisters, or a sign of delamination visible on the surface are in a critical state. These tyres are unsafe for use and require an instant replacement.

Tread separation, blowouts, or broken beads: These issues require immediate attention and the tyres must be replaced quickly to run the vehicle safely.

Multiple areas of repair: More than three local repairs or clustered repairs close together signal a tyre past its safe lifespan.

2. End of Service Life: Tread Depth and Age

The quality of a tyre’s tread design and its longevity also decide when you must replace it with a new one. Agricultural tyres age and lose their efficiency. The following are signs that you must replace the agricultural tyre due to aging:

Tread Wear: when tread lugs are less than 10% of the original height, field grip is reduced, and the tyre has poor traction, the tread design has worn out, and it can increase slip and cause the vehicle to lose control.

Rubber age and weathering: The tread might appear usable. But if the rubber has degraded in quality due to 5 to 10 years of use, it’s time to replace the tyre. Dry rots and persistent air loss are indicators of tyre ageing and the effects of weathering.

Vibration, noise, or persistent pressure loss: Irregular ride quality means internal tyre or ply issues.

3. Replacement Safety: Compliance and Best Practices

The tyre can be replaced due to compliance issues as well. It’s not ideal to mix tyres from different brands and sizes. Discrepancies in tractor tyre quality in different tyres cause inefficiency and safety issues.

Improper inflation and issues with mounting the tyre can damage it and prompt the vehicle to demand a replacement. It’s best to dispose of old tyres.

Repair vs Replace Tyres!

Tyres are more than expenses. Bias agriculture tyres are a boon to a thriving agricultural system. It ensures safety, productivity, and, most importantly, peace of mind out in the field. Knowing when to repair the bias ply farm tyre and when to replace it saves you from catastrophic failures and dangers.

At Birla Tyres, we have been able to engineer a range of agricultural tyres for the Indian field. Our intention to serve farmers with advanced technology and safe and practical tyres remains intact. Contact us for expert advice, and genuine replacement of the tyres, or any questions you have regarding farm tyre repair.

FAQ

Should I Repair or Replace my Tyre?

A: Tyre replacement depends on the level of damage it has endured. It also depends on aging and the effects of weathering. It’s best to replace a tyre that’s been in use for more than 5 years and has gone through several repairs.

When to Replace Tractor Tyres?

A: Inspect the tread wear bars regularly. If tread wear exceeds 10% of the original depth, the tyre should be replaced. The Tread Wear Indicator (TWI) provides the most reliable measure to assess when replacement is required.

Which Tyre Choice is most widely used in Agricultural Applications?

A: R1 tyres or the agriculture tyres offer much better grip, traction, and stability in field conditions. Irrespective of where you work—mud, loose dirt, snow, or somewhere else, R1 tyres provide the best traction you need.